Replacing the lower engine support Renault Logan is a simple job that even a novice car owner can handle, without involving specialists in the service station. Below we will consider what kind of detail it is, what is fraught with its failure, and how to extend the life of the back cushion.

Purpose and design features

Engine support Renault Logan is a product that provides support for the power unit and damages vibrations that occur during operation. Externally, it looks like a guitar, so in the environment of car owners and specialists in SRT, you can often hear this name (with reference to the pillow).

In the car Renault Logan installed three engine supports - left, right and rear (bottom). In the complex, they perform the following tasks:

- Extinguish the vibrations emanating from the running motor.

- Hold the motor in the static position.

- Exclude the appearance of extraneous noise in the cabin of the vehicle.

- Protect the power unit from shocks and vibrations that occur when moving along irregularities.

Initially, the support had the form of a metal element that attracted the motor to the body of the car. On modern cars (including Renault Logan) rubber cushions are installed, providing additional elasticity and protection from the appearance of knocking.

Where is the support?

Many car owners are unaware of the whereabouts of the Renault Legogne rear post and confuse it with other body parts. To find this site, you need to look under the car from below. The lower support structure is installed between the subframe and the gearbox. Its task is to protect the engine from excessive rolling. In the event of a malfunction of the support in the passenger compartment, additional vibrations and knocking may occur, which leads to discomfort during the movement.

Replacement of the bottom support of the engine Renault Logan: sequence of actions

To replace a failed component that holds the engine, follow these steps:

- Drive the car to a pit or overpass. You can also use the lift (if available). In extreme cases, replace the lower engine support of Renault Logan on a level platform. To do this, it is necessary to raise the front part of the jack and put the car on the supports for greater reliability.

- Prepare the key for "eighteen". To put under the engine a jack or to perform other preparatory steps is not necessary.

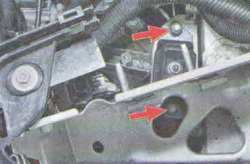

- Unscrew the two bolts that secure the lower support assembly.

The rear bolt must not be twisted completely, because the clamp holding the part is split. It is enough to release the fastener and the product can be removed.

- Remove the support and inspect it.

- Place a new product and screw the bolts in place. Remember that it is desirable to install original parts, which are recommended by the manufacturer Logan.

- Check the result of the work and make a test drive.

The replacement process is detailed in the video below:

How to choose the bottom support?

The best way to avoid problems in operation is to use only original replacement parts. Not the exception is Logan's lower cushion. Here it is better not to save and give preference to the details that the manufacturer recommends:

- The catalog number is 112383665R (original).

- The catalog number is 112381035R (original, French production).

If you want, you can buy a reinforced support - 8200 500 928. The proposed option is not original, but according to the car owners it serves a lot longer. The resource of this pillow is not less than the original spare part, and the price is lower.

During the installation process the bolts with graphite grease. After the work is completed, the result is immediately noticeable - vibration is reduced, the handle of the gearbox is shaking less, speeds are better included.

Features of operation

In order to replace the lower support as little as possible, it is important to know the operational features of this assembly. In practice, the pillow assumes the maximum load at the time of stopping or starting traffic. At the same time it works the entire period while the engine is turned on.

The need for replacement can be recognized by the following features:

- The appearance of visual damage (cracks or ruptures).

- Increased vibration in the cabin.

- The appearance of a strong kickback in the steering wheel.

- Jolts at the time of gear change.

- Knockout speed.

If you do nothing, there is a high risk of engine damage and even more expensive repairs.

The presence of cracks, the detachment of rubber from the metal part - an occasion to install a new part.

To avoid problems, it is enough to periodically inspect the condition of the unit and remove excess dirt and oil from it. From time to time, it is necessary to stretch the fixing bolts (in case they are loosened).

The average service life of the support is 80-100 thousand kilometers, but with proper operation it can last longer.

The time passes through our roads and the time comes when it is necessary to replace the engine mounts on our Logan. Many, this procedure frightens, because it's the same engine, a heavy and voluminous unit, which is the heart of our horse. In replacing the engine mounts there is nothing difficult, it is enough to have the desire and the necessary tool, which by the way can be found in any owner of Renault Logan. So, this article will describe in detail how to replace all the supports on the Renault Logan engine.

How to replace the right engine support Renault Logan

To perform work on replacing the right support we will need a jack with a spacer, car keys for 10 and 13, as well as a 16-gauge hex key. We prepare the instruments and proceed:1. Dismantle the motor protection.

2. We prop up the engine with a jack through the spacer, resting it in the crankcase.

3. We turn the bolt on the holder holder, which holds the adsorber purge hose.

4. We remove the hose in any direction for convenience of further work.

5. Remove the spacer from the hose attachment.

6. We turn out a pair of bolts which are screwed in fastening of the right support of the engine.

7. Remove the spacer above the support.

8. We turn out all bolts of fastening of the right support of the engine of Renault Logan in quantity of five pieces.

9. Then remove the support.

Everything, the operation to remove the right engine support was successful, accordingly we take a new right support and install in the reverse order.

How to replace the left engine support Renault Logan

To replace the left engine support we also need a jack with a spacer and a set of keys from the previous work. If everything is ready, proceed:The most important thing: there is no relay and fuse block in the photo, this is done for clarity, it is not necessary to remove it during the work.

1. Remove the battery.

2. Remove the motor protection.

3. Install the jack with the spacer under the engine, resting in the crankcase.

4. We turn away bolts of fastening of a support from картера transmissions.

5. Turn the pair of front bolts.

6. We unscrew a pair of back bolts of fastening of a support of the engine from a body longitudinal.

7. Remove the support.

As you can see, there is nothing difficult in removing the left engine support Renault Logan. After this, we take a new left support and install it in place in the reverse order.

How to replace the engine's rear support Renault Logan

To replace the rear engine support we need a key for 18, preferably an end, as well as a lift or pit, proceed:1. Remove the motor protection.

2. We turn away pair of bolts of fastening at an arm of a back support of the engine.

3. Remove the bracket.

4. Remove the bolt that secures the engine support to the subframe.

5. Remove the support.

This operation is the simplest of all replacements of the Logan engine supports, now you need to take a new support and collect everything in reverse order.

Hopefully, this article on replacing the engine mounts Renault Logan will serve you as a good tutorial when repairing your car.

Yes, and do not hesitate to comment!

The engine is the most important detail in the arrangement of any machine that vibrates quite strongly during operation. At the same time, vibrations are observed, even if the structure of the power unit is strictly balanced. Reduce the noise level and minimize the tremors help specific elements - the pillars (cushions) of the engine. These parts serve as a buffer, installed between the motor and the frame. They are designed to absorb vibrations in the cabin and keep the body in a static state, protecting it from accidental impacts while driving.

We can (non-original) for 843 rubles. Specify the actual prices for spare parts from a consultant.

The main task of the engine support for Renault Logan is to tighten the power unit as tightly as possible on the car body, while softening the transfer of vibrations from the active engine to the rest of the car parts. The nodes of the support do not allow the engine to move, despite the tremors that arise during its operation.

The number of control points in modern cars directly depends on the direction of the motor layout, as well as the engineering solution for the release of each specific model of the car. The main criteria for their design are high reliability of fastening and a low probability of displacement of the power unit to the side with sharp maneuvers. At the Renault Logan three engine supports are provided: the first is mounted on the timing side, the second is above the gearbox, the third is below the motor, supporting it in the longitudinal direction.

In order to keep the motor firmly attached to the supports, the supports must be strong and wear-resistant. The basis for the device is a strong metal construction, which in some cases is supplemented by rubber cushions. Modern manufacturers with success replace rubber in fastenings on polyurethane, differing by a long period of operation. Progressive mechanisms include special hydraulic supports of the power plant. They are able to adjust to different speeds and effectively cope with fluctuations at both high and low speeds. Today there are also so-called dynamic supports, on which a liquid with metal particles is used. This metal changes properties under the influence of a magnetic field, affecting the viscosity of the liquid itself. This adjusts the stiffness of the engine support.

The destruction of at least one of the supports of the power plant can lead to an excessive load on the car engine, so their condition should be under strict control by the owner of the machine. Checking the nuts and bolts on the engine mounts of Renault Logan, eliminating excess oil and dust from their surfaces are critical actions that will help extend the life of the mounts on the motor.

It is possible to suspect the problems in this unit if there is an unusually strong body vibration (in particular during a parking with an active brake for a car with an automatic gearbox) or when there are extraneous noise in the motor. Replacement of supports is necessary, if on them at visual inspection cracks and chips were found out, rubber parts were separated from metal details.

The engine supports of Renault Logan 2 (2014) are subject to replacement in case of wear. Signs of deterioration of the support is its cracking, gusts, excessive compression. This is shown in the following way: - Vibration from the engine is transmitted to the body; there is a displacement of the power unit;

Tools for removing the left engine support Renault Logan 2 (2014)

You will need "for 16", "for 18", keys "for 13", "for 16". It will be necessary to use the heads.

Operations to remove the left engine support Renault Logan 2 (2014)

1. Remove the battery, as it will interfere with the operations.

2. Remove the engine-ECU in the engine compartment.

3. Establish a support under картер transmissions. If the protection is installed, remove it first.

4. Remove the support fastening nut to the lower bracket.

5. Unscrew the two nuts securing the support to the upper bracket.

So there are nuts of fastening of the left support

6. Remove the rubber support

![]()

7. ... and a pillow.

8. Turn out 4 bolts of fastening of the top arm which fasten a support to a longeron of a body ...

9. ... and remove the upper bracket of the left engine mount.

10. Turn out a bolt of fastening of the pipeline of the hydraulic booster of a steering to the bottom arm.

11. Remove the air conditioning conduit from the holder on the lower support bracket