The cross-section of the current-carrying part of any type of cable products produced is one of the most important characteristics of it. In this case, if the insulating properties of the cable relate more to the location of the installation, the type of installation and the operating voltage, then the cross section is the value that directly affects the load on this network, that is, the power of the equipment to be connected. This parameter should be taken into account when organizing and designing absolutely any type of wiring, be it industrial facilities or private living quarters. For all types of electrical equipment, standard cross-sections of wires and cables are provided. It is measured in mm 2 and is calculated by the diameter of the current-carrying vein, as well as the area of the circle.

Standard series of sections

There is a standard series of wire cross-sections, manufactured by the manufacturers of cable products: 0.5; 0.75; 1; 1.5; 2.5; 4; 6; 10; 16; 25; 35; 50; 70; 95; 120; 150; 185; 240; 300; 400; 500; 625; 800; 1000; 1200; 1600 square meters. mm. At the same time, the maximum cross-section of the conductor can reach 6,000 mm. (cable КСВДСП-6000).

It is important to note that the minimum value for an aluminum cable is 2.5 mm 2. This is due to the low strength of this metal, since the number of bends before the refraction is much less than that of copper, that is, it can easily break down at the connection points, during installation.

Good to know

For private houses and apartments, where the linear voltage 0,4 kV and, respectively, phase 220 V is applied, the wire with the cross-section from the lowest value is most often used: 2.5 - aluminum and 1.5 mm.kv. copper. In general, such standard live wires are suitable for lighting circuits.

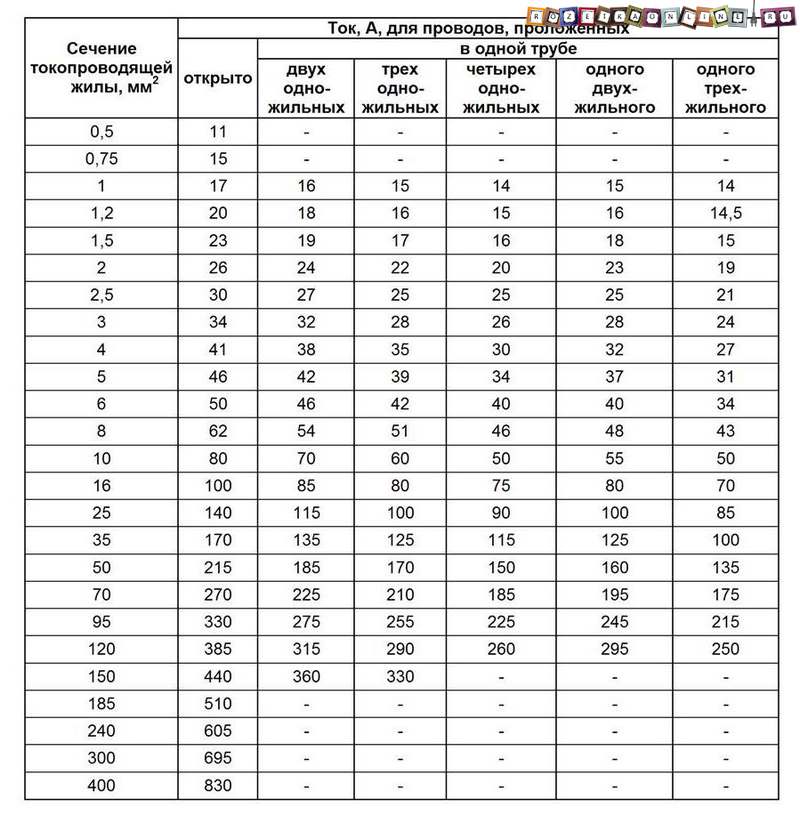

All other sections and, correspondingly, their diameters depend on the power and, of course, the current in the circuits of household electrical equipment. To determine the cross-section required for wiring installation, the table below is given. On it, knowing the total power of electrical devices connected to this network, you can easily find the right size of cores.

At the same time, it is recommended to select the section slightly with a margin, that is, the nearest larger standard value. For example, the voltage in the network is single-phase 220 volts and the owner of the room has a need to power devices with a power, say, 7 kW. According to the table there is no such power, but there are 5.9 and 8.3 kW. For copper wiring, a cable with a cross-section of 4 mm 2 core will be required. If the budget is limited and the task is to perform wiring from aluminum, the nearest larger parameter in the table will be 7.9 kW, which corresponds to a 6 mm 2 core.

It is also possible to combine wires of different cross-sections, for example from the input automaton to the junction box more, and then when there is wiring for groups of electric consumers or for luminaires, a smaller wire can be laid. The main thing is to remember the rules, in case there is such a need.

The production capacity of electrical equipment is much higher than in everyday life, and the voltage in high-voltage networks is 6 kV, 10 kV, 35 kV, etc. That is why the standard cross-section of wires and cables is more diverse. This value is calculated with a large margin, since the main most powerful receivers of electric power are electric motors, and during start-up they can increase the current in the power circuits supplying them 5-7 times higher than the nominal one.

However, for the supply of lighting equipment and secondary switching circuits carried out by control cables, all the same wires of 1.5-2.5 mm 2 are widely used and they are quite sufficient.

For power circuits of 6 kV, aluminum cable products from 120 mm 2 are often used. If this section of the cable is not enough, then start two lines connected in parallel to each other, thereby dividing the load on each of them. In the home, such techniques are impractical. There is for especially powerful equipment the installation of circuits with four or even six parallel wires connected.

There are cases when low-voltage circuits require cables with a rather large cross-section of cores, as, for example, in the case of welding operations.

The choice of the cross-section of the wire is very important and individual, that's why the whole designing bureaus or individual companies, which include experienced engineers, are engaged in this.

The question, by the way, is not simple. In particular, in accordance with the SN since the times of the USSR and up to now, the work with the cable is expensive, rather than with the wire. However, there was no very clear classification in this respect either in the past or today. Different sources provide different points of view. In practice, the "cable" or "wire" characteristic is assigned GOST / TU for the production of a particular brand. In particular, the cable of the GDP grade from Odeskabel OJSC differs from the PVS wire only by the shell configuration: the GDP cable is flat, and the PVS wire is round. And in no reference book on cables, the shape of the cable / wire sheath is not indicated as an unimportant factor. Therefore, it is necessary to look into the certificate - there will certainly be stated: it's a cable or wire.Cable cross-section calculation

There are reference signs indicating which section of the aluminum / copper core is needed for the assigned load. However, most electricians use a light formula (consider the load of 8kW.): A copper cable cross section of 1 mm2 can pass 10A or 2.2kW (power = 10A x 220V) through itself. Consequently, the load of 8kW in A will be 36A (load = 8kW / 220V), and for a similar volume, a cable with a cross section of 4mm2 will suffice. This calculation is more or less suitable for cables with a cross section of no more than 6 mm2. For large sections, however, tables are needed "On permissible current loads". With an equal load, the cross section of the aluminum cable should be almost 30% more than that of the copper cable. The cross-section of the cable is the area of the vein at the cut that conducts. The cross section of the round conductor of the cable is obtained according to the circle area formula = π × r2, where the number π = 3.14, and r is the radius. When there is a pair of wires in the vein, then the cross-section of the core will be equal to the sum of the cross sections of all the wires. The radius of the wire is measured with a caliper and very fine wires with a micrometer. What is the margin for the section needed? The stock, no doubt, will not be superfluous. However, one must know the limit. For example, the limit of any household sockets-switches is at most 16A (3,2kW = 16A x 220V) and the connection of a socket with a cable of 4mm2, with a capacity of 8kW is a frivolous expenditure of finance. And also, a cable with a cross section of 4 mm2 will not fit at all in each outlet. The rational cross-sections in household electric networks for copper: 1.5-2.5 mm2 for sockets and 0.75-1.5 mm2 for lighting.

Which cable is optimal: copper or aluminum?

Many "experts" with absolute certainty will say - copper. Why? For the consumer, copper in comparison with aluminum is advantageous in that copper, sooner or later, is not destroyed so vividly, and this is very significant when replacing luminaires, etc. Do I have to pay three times as much for this - the withdrawal for the consumer. BY THE WAY. Combine the copper and aluminum cables only with a terminal so that aluminum does not come into contact with copper. Because through some physical phenomena at the point of contact of aluminum and copper after a while increases. In consequence, the connection point is extremely heated, the cable breaks, appears, and in the extreme case - a fire. Among other things, the connection of all non-uniform materials with different results in a similar result. Because of this, you do not need to grind the wire with the first wire that has been met by twisting. Looking at the area of use of the cable, the conductor is made from a variety of materials: first copper and aluminum, then nichrome, steel, etc. When you are not assured of the uniformity of the material of the cables being combined, use a terminal.Which cable is optimal: flexible or hard?

A hard cable, usually a cable with a mono-wire core, and a flexible cable with a multiwire cable. The greater the number of wires in the core and how much thinner each wire is, the more elastic the cable. For flexibility, the cable is divided into 7 classes: mono - this is the 1st class, and the 7th class is the most flexible. With the increase in the class of cable flexibility, its price rises. A rigid cable serves for walling and laying in the ground, and flexible - for connecting maneuvering devices or electrical appliances. In terms of operation, which cable to choose - hard or flexible, it does not matter. In terms of installation - every electrician has his own wishes. By the way: the tips of the flexible cable, which are embedded in the sockets (switches), must certainly be stained or crimped with the help of special end caps. For a hard cable, this procedure is not necessary. To connect the lighting equipment, it is better to purchase a flexible cable, because the lighting fixtures are often replaced, and the hard cable breaks down more quickly when new electrical equipment is connected.How can I independently determine the quality of the cable?

Many manufacturers do not always comply with the standards when making a cable. Their main "trick" - is the understating of the cross-section of the current-carrying vein. And sometimes it is essential. Of course, to survey the cross-section at the point of acquisition is difficult. In the store you can measure all the wires with a caliper and a micrometer. The cable also comes with a lower thickness of the shell or with a shell of poor quality material, and this reduces the life of the cable. For inspection, it's a good idea to have as a standard a piece of the right cable. In stores, you can stumble upon a Chinese cable made of aluminum, covered with copper (sold as copper with a Cyrillic marking). Such a cable can be easily inspected: the sheath of the current-carrying conductor on the cable gleams white with aluminum. There are manufacturers who use copper or aluminum of low quality to reduce the cost. For such cables, the life and conductivity of the core are much lower than for GOST. It is possible to test the quality of metal conducting current in the following way:. try twisting and straightening the cable a couple of times. In factories, such a test is performed on a special bending mechanism under the determined radius of bending. Because of this, the number of bends before bending will be smaller for the number of bends stipulated in the GOST. However, in any case, aluminum should bear at least 7-8 bends, and copper - 30-40; . A cable made of high-quality copper / aluminum should be flexibly bent and not spring; . The copper / aluminum core on the stripped cable must have a bright (flashing) color. When lived - heterogeneous in color and there are hopeless spots - this is a fake. And nevertheless, the amateur will not be able to establish the quality of the cable on his own 100%. In this case, the recommendation is one - to rely on the brand. Of course, all domestic plants produce cable according to GOST.What kind of insulation and sheath should a cable have?

Clearly, it is best when the insulation and the sheath of the cable have double insulation. Cable with single insulation has a service life of up to 15 years, and in a double - 2 times longer. In the sources of information, it is generally accepted to disentangle the concepts of "isolation" and "shell". Insulation is a layer of dielectric material superimposed on the conductor core, and the shell - all layers on top of the insulation. The shell is designed to protect the cable from various influences. The cable can have a pair of layers of the shell of different types of material. Some types of shell that can be useful:. Heat-resistant cables for pulling in rooms with high temperature (sauna). Usually, the fluoroplastic material is used, and the top is fiberglass. There are no special signs for such cables, i.e. if necessary, one must seek help in directories or catalogs, where the meaning of the "operating temperature" is indicated without fail; . not supporting combustion with marking "ng" - means the ability to self-extinguish when the flame disappears, but not to endure high temperatures! . When the cable mark is "FR" (fireproof) and then E30, E90 or E120 - then this cable can "function" in the open fire for 30, 90 or 120 minutes; . cable with a polyethylene sheath can be stretched both in the soil and in an open way (for example, on the walls of houses); . cable with insulation and PVC sheath (polyvinylchloride) are used for pulling inside buildings (under plaster) or in cable ducts.The most famous cable brands

. wire PRV (copper), APPV (aluminum) in single insulation - for pulling inside walls; . cable ПВС (copper), gross national product (copper) in double isolation - for broaching inside buildings; . cable heat-resistant RKGM (copper) - up to 180 ° C, BPVL (tinned copper) - up to 250 ° C; . cable VVG (copper), AVVG (aluminum) - for stretching on the walls of houses and in the ground; . cable runway (copper) water-immersion - for pulling in water; . cable ТПП (copper) telephone paired - for pulling in the ground; . wire TRP (copper) telephone distribution for subscriber communication (including TA). cable "twisted pair" UTP, FTP - for the organization of computer networks, the inclusion of intercoms, etc .; . signal wire "Alarm" for connecting doorphones, security and fire alarms, etc .; . cable coaxial RG-6 for connecting TVs, antennas, CCTV cameras.Internet cable

The concept of "Internet cable" does not exist. Various information cables are used to translate information. If you have in mind the connection to the Internet, you need to check with the operator - what kind of cable should be stretched on the walls. At the same time, it is necessary to find out the brand of the cable and the manufacturer, so that then do not narrate about the bad cable and about the appropriate low speed of the Internet. For example, for the Internet use a regular TV cable TM Finmark, a twisted pair cable or an existing subscriber cable (the so-called "noodles") to which the phone is connected. On dedicated Internet lines can lay an optical cable.Computer cable

The term is incorrect. As a rule, a "twisted pair" cable is used to connect the PC to each other and to the server, however other information cables can be used. The technology to pair two veins in a pair has been used in telephony since the last century. The merit of the Americans is that due to the correctly calculated pitch and quality of the material, the transmission speed of information was much higher than that of a standard pair telephone cable. There are quite a few types of twisted pair cables depending on the number of cores, the diameter of each core, the circumstances of the laying, etc. Depending on the data transfer speed, the twisted pair cable is divided into groups: the 3rd category (standard telephone cable), the 5th category (office networks), the 6th category (the new generation cable for the 5th categories). "Twisted Pair", which has acquired the most popularity in our time - is a category 5 cable of 8 pair twisted wires, the core diameter is at least 0.45 mm and a maximum of 0.51 mm.TV cable

This is not the correct (household) name of the coaxial cable from 75. And also the wrong term - "satellite cable". Any coaxial cable for 75 can be used to connect a satellite and any other antenna, and to connect to cable television. It matters only one thing - whether it's a good cable or not. Signal attenuation and noise immunity are important characteristics of a coaxial cable. All other characteristics of the cable are aimed at improving the actual data of the 2 indicators and are of secondary importance. In particular, our cable RK is made only of copper wire (sometimes even silvered), but the attenuation of the RC cable will be almost four worse than that of any current RG cable produced from inexpensive materials: steel and aluminum. In the current period, the quality of the information cable is established by technology. When selecting a television cable, also consult the service provider.Audio cable

There are music lovers who have an audio cable that is as thick as a finger. There are masters who buy "vacuum-copper", silver-plated and even gold-plated cables. But some experts say that on proper measuring equipment, the differences between sound penetrated through an ordinary copper conductor and sound penetrated through the "super cable" are not noticeable. For all that, music lovers say that the difference is very audible to them. In the case where you are not a music lover, stretch out an arbitrary copper cable in the wall.In a three-phase network - 5 * 4mm.kv. (Cable consisting of five cores, each section 4mm.kv.) protected by a three-pole automaton 25A.

Why is it most often necessary for the correct operation of the hob to have a cable with the cores of this particular section, and most importantly, in which cases it is necessary to use a different cable, I will discuss below.

The principle by which the cable and the protective automatics for the hob are selected, does not differ from the choice of wiring for the rest of the apartment. The only correction is made for increased consumption of the power panel, those precious kilowatt of power, for which we ultimately receive bills.

Power - this is the main characteristic of the electric cooking surface, which you need to know for the correct calculation and selection of the supply cable and the protecting machine.

If you have already decided on a specific manufacturer and model, you will be able to find out exactly what power is consumed by looking at the description or asking the consultant in the store. But what if you have not made your choice and are delaying the purchase at the end of the repair? Do not forget about the possible breakage of the purchased hob after a while and the need to replace it with another.

For these and some other reasons i always advise and lay myself to my customers on the hob:

- in a single-phase network three-core cable ВВГнг 3х6 (or ВВГнгLS 3х6), with a section of each vein - 6мм.кв.

- in a three-phase network, a five-core cable ВВГнг 5х4 (or ВВГнгLS 5х4), with a section of each vein 4mm.kv.

To justify this choice, let's conduct a simple calculation of the cable's power selection.

The absolute majority of modern electric hobs for four burners consume about 7-8 kW (kilowatt) of power. That ideally corresponds to a current of 32 - 38 A (Ampere). To calculate the current strength by power, a formula is used for AC networks:

P = UI * cos φ , where P - power, U - voltage of the network, I - current, cos φ - power factor.

In our case P (Power) = 8000W (8 kW), U (household voltage) = 220V, I = 1, (power factor for the active load). From here it follows that

I (current) = 8000W / 220V = 36.4 A

Further from Table 1.3.4 of the Electrical Code (Rules of the Device of Electrical Installations) we choose the cross-section of the conductors of the cable. To look it is necessary in a column for a two-core copper cable as the third vein - grounding, at normal conditions of work of the electric panel it is not involved.

The most suitable variant of a copper cable for a hob in a single-phase network according to the table is 6mm.kv, since it can withstand current in 40A. This is also confirmed by information posted on the sites of cable manufacturers. Such a cable (ВВГнг 3х6мм.кв) it is accepted to protect by the automatic machine or the differential automatic device face value 32A.

At the very beginning, I also indicated the possibility of using a five-core cable in a three-phase network with a cross-section 4kv.m.. You may think that this is not very universal, because you will need to buy a hob designed to work in a network with voltage 380V - but it is not. The absolute majority of modern hobs or plates are designed for tension 220-240V. In this case, there is a possibility of two- or three-phase connection. Read more about these three cascades connecting hobs or electric stoves.

If you remember that between each phase and zero voltage 220V, everything falls into place. Inside the electrical panel, there is simply a phase separation for different burners. It turns out that almost every burner has an individual connection with a cable of 4 mm.kv section, while the power consumption of each of them is much less than that of the whole plate. According to Table 1.3.4 of the Electrical Code, the cable cross-section of 4 mm.kv conductors, safely withstands 27A, it is about 5.9 kW (see in the column of three-wire). This cable (ВВГнг 5х4мм.кв) is accepted to be protected by the automatic machine or the differential automatic machine in nominal value 25А.

Usually, this is quite enough for the connection and proper functioning of most electrical kitchen surfaces, but what if it is known in advance that the device will be more power-consuming and its consumption is permissible 10-12 kW? It is quite simple to calculate the cable selection according to the power of the consumer, similar to what we did above. Let's repeat.

Calculation of the cable cross-section by power with your own hands

The choice of the cable for the hob starts with the calculation of the current, with the known indicators for us: Power of the hob P = 12kW = 12000W. Voltage in the household network - U = 220B, the power factor for the hob cos φ = 1. We substitute all the values in the formula by which the power in the alternating current network is determined.

P = U * I * cos φ, from this formula we find the current.

I (current) = P (power) / U (voltage) * cos φ (power factor) = 12000/220 * 1 = 54.6A

Then again refer to Table 1.3.4 of the PUE and see that we have almost no stock like a cable with a cross-section of cores 10mm.kv with indicator I = 55A. Or if the network is three-phase, you can take a five-core cable - section 5 * 6mm.kv.

And in the end, to confirm your words, and most importantly for greater your confidence in the correctness of their actions, I quote from SP 31-110-2003 (Code of rules for design). Design and installation of electrical installations for residential and public buildings p.9.2 paragraph 2.

« In apartments of apartment houses equipped with electric cookers, a separate group line for feeding these plates should be provided (14.27). Lines for feeding single-phase electric stoves must be made with copper conductors of at least 6 mm2.»

It should be noted that this article was only about the hob, in the case of an electric stove (combining the surface with the oven) or in the case of a joint connection with the built-in hob of an electric oven, the cable cross-section may be required different, for a larger capacity. Knowing how to calculate and select the cable for the power of the device, you can easily select the right option for the plate.

And yet, do not be afraid of the choice of a circuit breaker of a smaller value than the rated current for the plate. This is the topic of a separate article, for now, take a word.