LIGHTING OF INDUSTRIAL PREMISES

Influence of lighting conditions on performance, safety and productivity

Light is a natural condition of human life, playing an important role in maintaining health and high efficiency. It has a positive effect on a person's emotional state, metabolism, cardiovascular and central nervous system.

The visual analyzer of the person is the main source of the information received by him about the external world.

Thus, being an important indicator of occupational health, industrial lighting is designed for:

Improvement of the conditions of visual work and reducing fatigue;

Increase of labor safety and reduction of occupational diseases;

Increase of labor productivity and quality of products.

Light is part of the electromagnetic spectrum of visible radiation (λ = 0.38-0.77 μm).

Basic lighting values and measurement units

Light engineering quantities quantify the effect of light radiation on the human eye. Usually, quantitative indicators such as luminous flux, luminous intensity, illumination, surface brightness, reflection, transmittance and absorption coefficients are used.

luminous flux (F) - the radiation flux estimated by its impact on people. eye.Za unit - LUMEN (lm)

intensity of light (I) - spatial density of light flux, cat. determine the ratio of the light flux F to the body (spatial) ω, in the cat. it spreads. For the unit of luminous intensity accepted candela (cd). The solid angle is part of the space of the sphere, bounded by a cone reflected on the surface of the sphere, with the vertex at its center. The unit of solid angle is steradian (cp).

illumination (E) is the surface density of the light flux F. With a uniform distribution of the light flux perpendicular to the illuminated surface S, the illumination  . Measured in lux (lux)

. Measured in lux (lux)

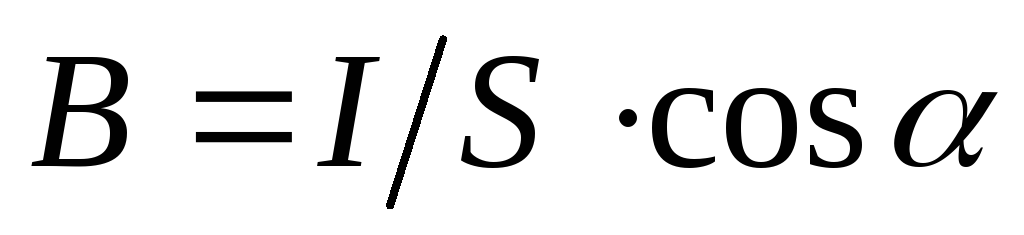

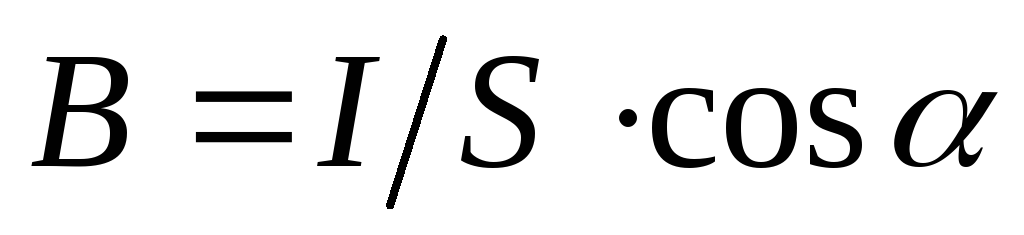

the brightness of the surface (B) - is the surface density of the force of light and is defined as the ratio of the strength of the light I in a given direction to the projection of the luminous surface on a plane perpendicular to the direction of observation.  , where ά is the angle between the normal to the surface S and the direction to the eye. Per unit. brightness candela per m 2 (cd / m 2

).

Brightness is light. value, the cat. directly perceives the eye people. Visual sensations are determined by the brightness of the illuminated surface, depending on its color, roughness, and other factors. Excessive brightness causes short-term fading

, where ά is the angle between the normal to the surface S and the direction to the eye. Per unit. brightness candela per m 2 (cd / m 2

).

Brightness is light. value, the cat. directly perceives the eye people. Visual sensations are determined by the brightness of the illuminated surface, depending on its color, roughness, and other factors. Excessive brightness causes short-term fading

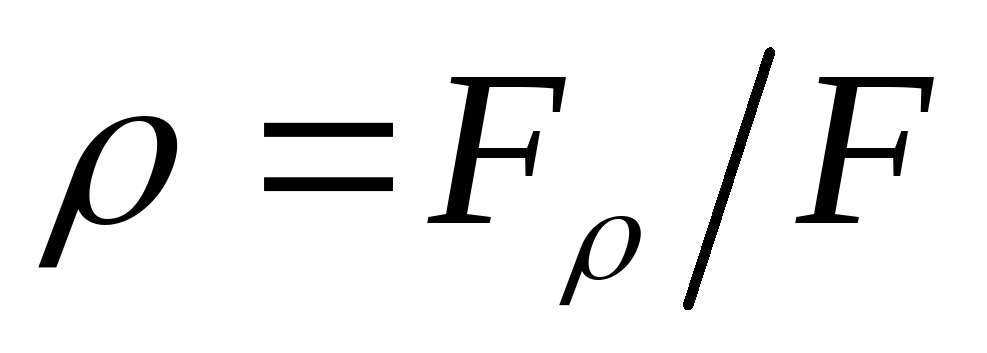

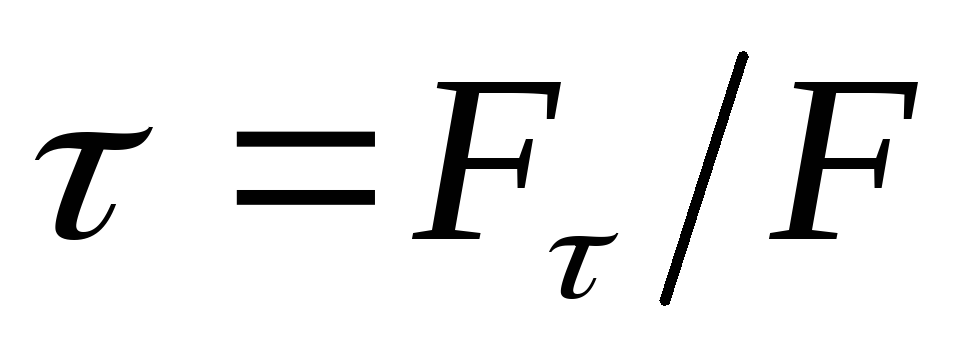

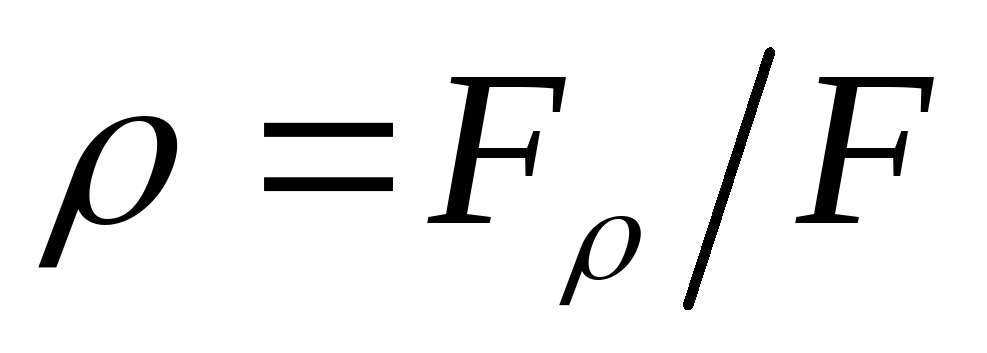

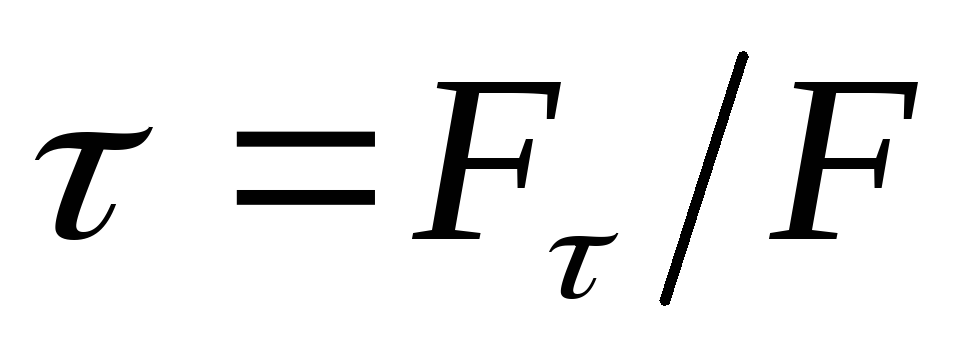

reflection coefficients ρ, transmittance τ and absorption β of surfaces are measured in% or fractions of unity.

,

,

,

, , where F ρ, Fτ, F β are respectively reflected, absorbed and transmitted through the surface light streams

, where F ρ, Fτ, F β are respectively reflected, absorbed and transmitted through the surface light streams

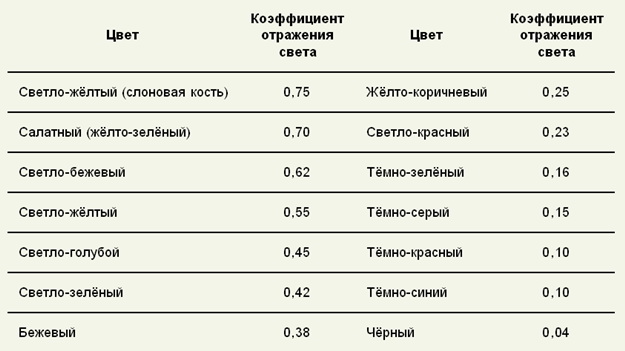

FON is the surface. directly adjacent to the object. The background is light at ρ\u003e 0.4, the average at 0.4\u003e ρ\u003e 0.2, dark at ρ<0,2

The contrast of the K-object of observation and the background is determined by the difference between their brightness

K = (Bo-Bf) / Bf, where B0 and Bf are the brightness of the object and the background

The effect of light on the human body

Light is one of the most important conditions for the existence of people. It affects the condition of the body. Correctly organized lighting stimulates the processes of nervous activity and increases efficiency. When there is insufficient lighting, people. works less productive, quickly becomes tired, the probability of side effects increases, which can lead to injuries. It is believed that 5% of injuries can be the cause of such prof. diseases like working myopia (nearsightedness)

Depending on the wavelength, the light can exert an exciting (orange-red) or calming (yellow-green) effect.

The spectral composition of light affects the productivity of labor. Studies show that if the production of people. under natural light take for 100%, then with red and orange lighting it is only 76%. In humans, the cat. for some reason, partially or completely deprived of natural light, light starvation may occur. With good lighting eliminates eye strain, accelerates the pace of work.

Natural and artificial lighting, their sources, rationing.

Kinds and systems of illumination

Depending on the light sources, industrial lighting can be natural, artificial and combined.

Natural lighting in the room can be formed by direct sunlight, scattered light of the sky and reflected light of the earth and other objects.

Artificial lighting is created by incandescent lamps or gas-discharge lamps.

Combined lighting is an addition of natural lighting artificial in the dark and light time of day with insufficient natural light.

The natural light in its spectral composition is significantly different from artificial light.

In the spectrum of sunlight, there are much more than the ultraviolet rays necessary for man, it is characterized by high diffuseness (scatteredness) of light, which is very favorable for visual working conditions. Natural lighting provides visual contact with the external environment, eliminates the monotony of the lighting situation in the rooms, causing premature fatigue of the nervous system.

Considering the high biological and hygienic value and positive psychological impact of natural light, in practice they strive for the maximum possible use of it in the design of industrial lighting.

Premises with a permanent stay of people should, as a rule, have natural light.

By design features daylight it happens: lateral, when light penetrates into the room through the light apertures in the outer walls, windows; upper - through the upper light apertures, lanterns; combined - a combination of side and top lighting.

Since the level of natural light can change dramatically in a short time, the normalized value (quantitative characteristic) of natural light is not the illumination of the workplace, but the coefficient of natural light (KEO).

The natural light factor (e) is the ratio of natural illumination at a reference point inside the room (  Ev) to the simultaneous value of the external horizontal illumination (En), created by the light of a full open sky.

Ev) to the simultaneous value of the external horizontal illumination (En), created by the light of a full open sky.

KEO It shows what part of the external illumination is the illumination at a certain point inside the room

KEO (e) =  %

%

Artificial lighting for functional purposes is divided into working, emergency, evacuation, security and duty.

Work lighting is arranged in all rooms, as well as areas of open spaces intended for work, people's passage and traffic.

Artificial working lighting can be general and combined, when a local, concentrating light flux is directly added to the workplace. The use of one local lighting inside buildings is not allowed.

Depending on the location of the equipment and workplaces, the overall lighting can be uniform or localized.

Emergency lighting is provided in all cases where a sudden disconnection of the main lighting can cause an explosion, fire, people poisoning, the risk of injury, prolonged disruption of the process or malfunctioning, communication centers, water and gas supply installations, duty posts and control points for various systems.

Evacuation lighting is provided in the aisles of industrial buildings with a number of employees more than 50 people, where the exit of people from the room with sudden disconnection of working lights is associated with the danger of injury.

Security lighting is provided (in the absence of special technical means of protection) along the boundaries of the territory, protected at night.

The attendant turns on outside working hours.

Artificial lighting is estimated by the amount of illumination (E, lk).

The sources of artificial lighting can be incandescent and gas-discharge lamps.

The service life of incandescent lamps is up to 1000 hours, and light output from 7 to 20 lm / W. The greatest advantages are iodic incandescent lamps. They have a service life of 3000 hours, and a light output of up to 30 lm / W.

Visible radiation from incandescent lamps prevails in the yellow and red parts of the spectrum, which causes distortion of color reproduction, makes it difficult to distinguish the shades of colors.

Gas discharge lamps have light characteristics that more fully meet hygiene requirements. At them the radiation of the optical range of the spectrum arises as a result of an electric discharge in the atmosphere of inert gases, metal vapors and their salts. The service life of gas-discharge lamps reaches 14 000 h, and the light output - 100 lm / W.

By selecting inert gases and metal vapors in the atmosphere of which the discharge occurs, it is possible to obtain a light flux of gas-discharge lamps in any part of the spectrum.

In gas-discharge lamps, a balloon is filled with mercury vapor and an inert gas, a phosphor is applied to its inner surface.

The most common gas discharge lamps are low-pressure and luminescent lamps in the form of a cylindrical tube. They are produced in different colors: fluorescent lamps (LD); cold white color (LHB); white color (LB); Heat-white (LTB) and with improved color rendition (LDC).

fluorescent lamps are a glass tube, the inner surface of which is covered with a phosphor. The passage of Eltok through this mixture is accompanied by the emission of ultraviolet rays invisible to the eye, which cause the luminescence to glow. Thus. in fluorescent lamps, the electricity first turns into ultraviolet rays, and then, with the help of a phosphor, into visible light. Applying various phosphors can give the lamps a different color, including close to daylight.

fluorescent lamps have a small brightness and therefore do not have a blinding effect on the eyes, the surface of the lamp tube is slightly heated (40-50). The disadvantages of fluorescent lamps include the fact that for ignition and stabilization of the combustion mode, a special ballast is necessary, which complicates their operation and reduces the efficiency. Lighting from a fluorescent lamp can cause stroboscopic effect , which consists in the fact that, due to the absence of thermal inertia, the rotating parts of machines illuminated by a lamp may appear to be stationary or rotating in the opposite direction. This effect can be reduced by including neighboring lamps in different phases of the network, but it can not be completely deleted. The main disadvantage is the greater sensitivity to changes in ambient temperature. The normal mode of operation of the lamp is provided at ambient temperature of 18-25 ° C

High-pressure discharge lamps include metal halide, sodium, arc, mercury, xenon and others.

Mercury lamps, unlike luminescent lamps, light up steadily and work well both at high and low temperatures of the ambient air. They have a large capacity and are used mainly for lighting high industrial premises and streets.

Xenon lamps consist of a quartz tube filled with xenon gas. They are used to illuminate sports facilities, railway stations, construction sites. They are sources of ultraviolet rays, the effect of which can be dangerous when illuminated with more than 250 lux.

The most promising are halogen lamps, the discharge of which occurs in the vapor of halide salts, as well as sodium lamps. They are characterized by excellent color rendering and high efficiency (light output 110-130 lm / W).

With combined lighting, the general artificial lighting of rooms should be provided with gas-discharge lamps. The use of incandescent lamps is allowed in cases where, according to the conditions of technology, environment or requirements for interior design, the use of gas-discharge lamps is impossible or impractical.

Combined lighting is estimated by the natural light factor when disabling artificial light sources.

The norms of production lighting are set according to:

Characteristics of visual work (the smallest object size of discrimination, luminosity of the background, the contrast of the object with the background;

Discharge and sub-division of visual work;

Kinds and systems of illumination (for artificial illumination).

For the 1st: the object of discrimination is determined by the smallest size of the object (part) or part of it, which must be distinguished (learned) during the execution of this work (eg, point, wire thickness, etc.).

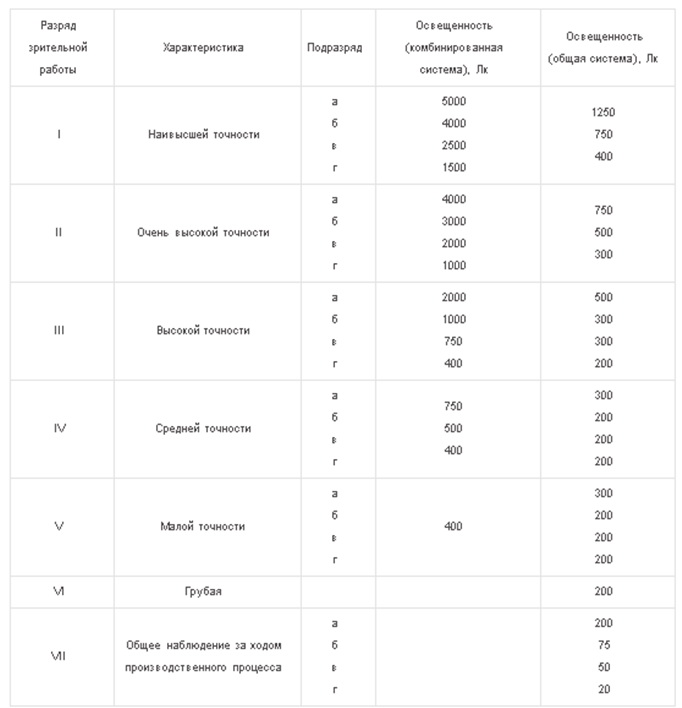

For the second: depending on the size of the object of discrimination and the distance of the object from the eyes of the worker, all works are divided into 8 digits of accuracy, which, in turn, are divided into sub-sections (a, b, c, d) depending on the contrast of the detail of discrimination background and the reflection coefficient of the background. For each subsection, the norms set a certain value of the illumination and natural light factor, which decrease as the size of the parts increases, the contrast with the background and the reflection coefficient (the background is the surface adjacent to the object of discrimination on which it is considered)

Requirements for lighting workplace

- Illumination in workplaces should correspond to the nature of visual work

A fairly even distribution of brightness for a slave. surfaces

Absence of sharp shadows on the slave. surfaces

Lack of glitter

Constancy of illumination in time

Correct color rendering

Provision of electrical, explosion and fire safety

Economy

Artificial light in its spectral composition should approximate the natural

The lighting of the working area must satisfy the trace. conditions:

Light level slave. surfaces must comply with the hygienic standards for this type of work

It should be ensured uniformity and stability of the level of illumination in the room, the absence of sharp contrasts between the illumination of the office. surface and environment. space

In the field of view, no light should be created by light sources, etc.

Artificial light in its spectral composition should approximate the natural

SUBJECT: 2 BODIES OF OVERSIGHT AND CONTROL OF COMPLIANCE WITH LABOR LAW. SYSTEM OF SAFETY STANDARDS OF LABOR

Supervisory bodies and control over observance of labor legislation in the Republic of Belarus .

Supervision and monitoring of compliance with labor legislation is carried out by specially authorized state bodies acting in accordance with the legislation.

The control is carried out on 3 levels:

State;

Public;

Departmental.

State Committee of theuda - develops drafts of normative acts regulating responsibility for the state of working conditions, and monitors the provision of benefits and compensation for unfavorable working conditions.

State Labor Inspectorate- Supervision and control over compliance with labor legislation, imposing sanctions on employers and officials for violating it, providing the employer and employees with technical and legal information and recommendations for the application of legislation, coordinating the activities of state supervision bodies, specialized and departmental labor protection inspections.

Gospromatomnadzor(State Committee for the Supervision of Safe Work in Industrial and Nuclear Energy) - directs its activities to identify the causes of conditions that contribute to the occurrence of accidents and industrial injuries, monitors compliance with safety requirements when operating equipment, carrying out blasting operations, etc.

Gosenergonadzor(State Committee for Energy Supply and Energy Supervision) - oversees the use of electrical installations, stations in enterprises and organizations.

Gossanadzor- carries out control over the implementation of sanitary and hygienic measures aimed at eliminating and preventing pollution of the external environment, as well as monitoring the organization and conduct of activities aimed at reducing and preventing morbidity, guided by the healthcare legislation and acts of the Ministry of Health.

SERVICES OF THE STATE FIRE SUPERVISION- The Ministry of Emergency Situations - supervise the compliance with the fire fighting regime at the facilities

Prosecutor supervision- resolves the issue of the responsibility of the person who committed a violation of legislative acts.

Public controlcarry trade unions.

Departmental control- Control of departments and ministries.

Responsibility of officials for violation of legislation:

disciplinary- consists in imposing the following penalties on the perpetrators: a remark, a reprimand, a demotion, dismissal;

administrative- fine, deprivation of special. rights, prevention, corrective work; material;

criminal- The penalty is determined depending on the gravity of the crime and can be in the form of a fine, dismissal, correctional labor or imprisonment for up to 5 years.

The system of labor safety standards (SSBT), its importance and structure .

Currently in the Republic of Belarus there is a SSBT common for all branches of the national economy.

SSBT- a set of interrelated standards containing requirements, norms and rules aimed at ensuring the safety, health and human performance in the work process.

The SSBT is an integral part of the state system of standards.

The following categories of standards are established:

GOST - state standard;

OST - branch;

PCT - Republican;

STP is the standard of the enterprise.

for example, GOST 12.4.089-80 SSBT

GOST - the index designating the state standard;

12 - cipher of state standards;

4 - number of the subsystem, indicating the requirements for means of protection for employees;

089 - the serial number in the subsystem;

80 - the last two digits of the year of registration of the standard.

If after the year of publication there is an asterisk (eg, 80 *), then it means that the standard is reprinted with changes.

Standards subsystems 0,1,2,3,4,5 and issues reflected in the their.

Standards included in the SSBT are subdivided into subsystems, denoted by numbers from 0 to 5:

ABOUT- organizational and methodological standards that establish the structure of the SSBT, the terminology in the field of occupational safety, the classification of hazardous and harmful production factors, the organization of training of working safety and so on;

1 - standards of requirements and norms for the types of hazardous and harmful production factors, establishing their maximum permissible values, methods of monitoring and protecting workers;

2 - safety standards for production equipment, those standards are included that establish safety requirements for the design of the equipment and its components;

3 - standards of safety requirements for production processes, includes standards that establish safety requirements for technological processes, production equipment, workplaces, personnel mode of operation;

4 - standards of requirements for means of protection for workers, establish requirements for protective and hygienic means of protection, as well as methods for their testing and evaluation.

5 - standards of safety requirements for buildings and structures.

The rights and duties of the state labor inspectorate

The Labor Inspection Committee under the Ministry of Labor is the state body responsible for supervising and monitoring compliance with labor laws and rules on health care. He exercises control over the whole range of issues related to the organization of work on health, at all stages of the production process, all enterprises regardless of the form of ownership.

State inspectors of labor are given the right:

to visit enterprises without hindrance

to get acquainted with any documents and to remove from them copies, if there are no legislative restrictions

receive from managers. officials and employees of an explanation on the matter m falling within their competence

withdraw and take with them for analysis samples of used and processed materials and substances, provided and notify the employer and the absence of legal restrictions

In case of violations:

1) issue to the lessee mandatory regulations

2) suspend (prohibit) the work of shops, plots, equipment

3) impose fines on officials and employers

4) raise the issue before the relevant authorities on bringing to justice officials for violation of labor laws and rules on health care

Responsibilities of the OT inspection committee:

carry out organization of work on HSE

conducts a special investigation of accidents at work

to conduct selective examination of under construction, reconstructed and operated production facilities

THEME: 3 ORGANIZATIONAL STRUCTURE OF LABOR PROTECTION. KINDS OF TRAINING TO SAFE LABOR METHODS. ORGANIZATIONAL-TECHNICAL, SOCIAL-HOUSEHOLD MEASURES FOR LABOR PROTECTION.

Regulations on the organization of work on labor protection in the enterprise. Labor Protection Service .

Proper organization of work on HSE is of paramount importance for increasing labor productivity, eliminating the causes of accidents and occupational diseases. Organization of work on HSE at the enterprise is determined by special documents (occupational safety management system, work system for HSE). which determine the duties of the company's officials on HSE, the procedure for planning work on HSE, control of this post.

The general guidance on labor protection in the enterprise is provided by the enterprise manager and engineer, heads of structural divisions.

The head of the enterprise carries out measures to create safe and healthy working conditions, i.e. responsible for the organization of labor protection in general in the enterprise.

The chief engineer monitors compliance with rules and regulations on labor protection, safety, industrial sanitation, fire safety.

The chief engineer manages the development of plans for work on the OT, analyzes the causes of injuries and morbidity in the workplace, organizes the execution of orders from higher and supervisory bodies. Systematically checks the state of TB at the enterprise and the sanitary and hygienic working conditions and takes measures to eliminate the identified shortcomings. In addition, the Chief Engineer approves the acts of accident investigation, promotes the OT and provides the workers with instructions and rules on HSE, organizes the testing of knowledge and skills development of managers and specialists on HSE issues.

All large enterprises are organized labor protection service. The labor protection service is subordinated directly to the head of the enterprise or his deputy.

The main tasks of the labor protection service are:

organization of work to ensure workers' health, prevent occupational injuries and occupational diseases, eliminate (reduce) production hazards;

control over the implementation of labor safety requirements, compliance with legislation, rules, norms and instructions on HSE;

counseling and provision of methodological assistance to officials, heads of departments and other workers on OT, correct application of the provisions of labor and health legislation.

Instruction and training of communication workers in safe working methods. The system for conducting briefings, the types, their characteristics, the methodology forreference.

Training of workers in safe working methods is carried out with the help of briefings.

The following types of briefings are given: introductory;

primary in the workplace;

repeated;

unplanned;

Induction trainingconducts an OT engineer with all employees who are first accepted for permanent or temporary work, regardless of their education, work experience, position, as well as with students, students in the passage of production practice. Introductory briefing is conducted according to a program approved by the employer. The program provides general information about the company, hazardous and harmful production factors, familiarity with the rules of internal labor regulations, etc.

Initial briefingat the workplace before the start of production activities conducted with all workers employed; employees transferred from one unit to another; employees who are doing a new job for them. Initial briefing is conducted with each employee individually with a practical demonstration of safe methods and methods of work.

Repeated briefingall employees regardless of qualification, education, length of service, type of work performed at least once every six months, except for persons who are not connected with the maintenance, testing, adjustment and repair of equipment, storage and use of raw materials. These persons can not be instructed in the workplace. Repeated briefing is conducted to assess the knowledge of the rules and instructions for the OT.

Unscheduled Instructionwell spend at:

introduction of new or revised regulations on RT;

change of technological processes, replacement or modernization of equipment;

violation of the normative legal acts on OT.

Targeted briefingspend at:

execution of one-time works, not related to direct duties in the specialty (cleaning the territory, etc.); liquidation of consequences of accidents, natural disasters; conducting an excursion at the enterprise, organizing mass events with students (hikes, etc.).

Primary, repeated, unscheduled and targeted briefings are conducted by the immediate supervisors of the work. Instructions in the workplace are completed by interviewing and testing the acquired skills of conducting safe work. The briefing is recorded in a special journal.

Planning and financing of labor protection measures .

The following types of plans are being developed:

1) prospective (five-year plans): these are comprehensive plans to improve the OT, are part of the plans for the economic development of the enterprise;

2) current (annual) plans for RT included in the agreement of collective agreements;

operational (quarterly, monthly) plans for the branches of the economy.

Before development perspective (integrated) plans it is recommended to carry out certification and certification of the state of working conditions in the workplace. This will make it possible to determine the number of people engaged in heavy, dangerous and harmful work and the plan for reducing them, to determine the number of jobs that do not meet the standards for sanitary and technical factors (noise, vibration, temperature) and a plan for their elimination; identify traumatic areas.

The development of a comprehensive plan is carried out under the guidance of the head or chief engineer and the chairman of the trade union committee, is submitted for discussion by labor collectives.

The report on the implementation of the plan is issued in the form of statistical reporting No. 21-t "Report on the implementation of a comprehensive plan to improve labor protection and sanitation."

Annual plans (current planning) are made on the basis of 5-year-olds and are detailed. Here, measures are planned for the modernization of production equipment to ensure safety and working conditions, the installation of safety and security devices, the application of identification and security signs in accordance with GOST, the provision of overalls, special footwear and other personal protective equipment, etc.

Operational planningincludes the elimination of deficiencies identified by the bodies of the State Supervision Service as a result of inspections, verification of the training of persons, etc.

The activities are financed by:

the amortization fund, if the activities are carried out simultaneously with the capital repair of funds; capital investments, including the production development fund, if the activities are capital;

overhead costs, if they are non-capital nature. The report on the use of funds on the PA is drawn up in the form No. 7-tvn "Information on the costs of measures for the OT

TOPIC-INDICATORS OF THE STATE OF LABOR PROTECTION. METHODS OF ESTIMATION AND ANALYSIS OF THE STATE OF LABOR PROTECTION.

Dangerous and harmful production factors .

A dangerous production factorcalled such a factor, the impact of which on the worker under certain conditions leads to trauma or other sudden sharp deterioration of health. Hazardous factors are: electric current, moving parts of machines and mechanisms, unprotected moving parts of production equipment, increased surface temperature of equipment

A harmful production factorcalled such a factor, the impact of which on the worker under certain conditions leads to a disease or a decrease in working capacity. Harmful production factors include noise and vibration of machines, equipment, electromagnetic fluctuations, insufficient or excessive illumination, dustiness and gas pollution of the environment, excessive neuropsychic and emotional stress.

All dangerous and harmful production factors are divided by nature into:

physical factors- are moving machines and mechanisms, moving parts of machines; increased level of harmful aerosols, vapors, gases, increased or increased temperature, etc .;

chemical factors- These are lubricants, acetone, carbon dioxide, varnishes, paints, enamels and many other chemicals;

biological factors- Pathogenic microorganisms (bacteria, viruses), as well as macroorganisms (plants and animals);

psychophysiological factorsare physical overloads (static and dynamic) and neuropsychiatric (mental overstrain, monotony of labor).

All harmful substances are hazardous and harmful production factors. In its physical state, it can be gases, dust, vapors, fumes, fogs, liquid, solid, loose bodies. Many substances in a mixture with air form aerosols.

Aerosols with particles formed as a result of grinding of solids (minerals, soil, sand, etc.) are called dusts. The settled dust is called aerogelsand Aerosols with solid particles formed by volumetric condensation of supersaturated vapors, combustion and other chemical reactions are called smoke.Aerosols with liquid particles are called fogs.

By the degree of exposure to the body, harmful substances are classified into four hazard classes:

1- extremely dangerous

2- Highly dangerous

moderately dangerous,

low-risk

The main unfavorable production factors at the enterprises are: increased noise level, increased neuro-emotional tension, harmful chemicals in the air of the work area, exceeding the maximum permissible concentrations in the workplace.

The creation of favorable conditions at the workplace primarily involves the complete elimination or reduction to safe levels of the values of hazardous and harmful production factors.

Traumatism and disease at work, their causes are causing .

Work Injury- this is a trauma received by a worker in the workplace and caused by non-compliance with labor safety requirements.

The set of injuries received during work, characterizes occupational injuries.

Industrial injuries, in contrast to occupational diseases, carry an element of surprise.

Injuriescalled damage to the tissues of the body and the violation of its functions in case of accidents, i.e. when exposed to working dangerous production factors.

They may be:

mechanical (bruise, cut, fracture, dislocation, etc.);

thermal (burn, frostbite);

chemical (chemical burn);

electric (burn, skin metallization, electric shock, etc.);

psychological (nervous stress, fright, etc.).

Injuries can lead to temporary or permanent disability. In this case, the victim may lose the general working capacity or only professional. With the loss of professional capacity, he can not work by profession, but can be used in other jobs. With the loss of general working capacity, the victim partially or completely loses the ability to perform any work.

Unfavorable working conditions can cause occupational and general diseases.

Occupational diseasesarise under the influence of harmful production factors. They can cause temporary, prolonged or permanent loss of ability to work.

A special case of occupational disease is professional poisoning.

Occupational diseases according to the principle of origin are divided into:

occupational diseases caused by physical factors. They include a vibration sickness caused by vibration on the human body; Hearing loss, occurring with systematic and intense noise exposure, etc.

occupational diseases caused by dust. These include chronic professional fibrosis of the lungs, as well as chronic dust bronchitis, etc.

occupational diseases due to exposure to chemicals. These include acute and chronic poisoning, acute and chronic skin diseases - dermatitis, eczema.

The Ministry of Health of the Republic of Belarus approved a list of occupational diseases. It is used by doctors for legal recognition of the disease by a professional, as well as when assigning temporary disablement benefits, disability pensions and when considering issues related to compensation for damage to businesses caused by health.

The causes of occupational injuries and diseases can be divided into the following groups:

- technical reasons- this is the design faults of machines, tools or their malfunction; absence, malfunction of fencing, blocking devices;

organizational reasons- non-compliance with the rules of TB, the lack of knowledge of the injured person, improper work practices, shortcomings in the organization of the workplace, lack of personal protective equipment, violation of labor discipline, lack of supervision when performing work with increased danger;

sanitary and hygienic causes- high content of harmful substances in the air, high noise level, irrational lighting, unsanitary conditions of premises, non-observance of sanitary norms;

psychophysiological reasons- monotony, high tension of work, fatigue.

Methods for analyzing the causes of accidents .

Based on the acts of FN-1 and the materials of investigations of accidents, the causes that caused them are analyzed. The analysis can be carried out by several methods of statistical, monographic, group and topographical.

Statistical methodbased on the study of the causes of injuries according to the acts of FN-1 for a certain period of time. This method allows you to determine the dynamics of injuries, identify patterns and relationships between circumstances and the causes of accidents.

Relative statistical coefficients of frequency and severity are used to assess the level of injuries.

The frequency of injury rate CKdetermines the number of accidents. per 1,000 employees for a certain calendar period (year, quarter):

Кч = Т / Р * 100%,

where T is the number of accidents for a particular period;

P - average number of employees

Severity of injury rate K t characterizes the average length of incapacity for work per incident:

K m = D / T * 100%,

where D is the total number of days of incapacity for work for all accidents.

Group methodanalysis allows you to distribute accidents by types of work, dangerous and harmful production factors, information about the victims (age, sex, work experience, etc.), date of the incident (month, day, shift, hour of the working day).

Topographic methodis to study the causes of accidents at the place of their occurrence in the enterprise. At the same time, all accidents are systematically applied to the plans of the enterprise by conditional signs, resulting in the formation of a topogram on which workplaces and places with increased traumatic danger are clearly visible.

A clearer idea of the causes of injuries can give monographic method of analysis. It consists in a detailed study of the whole complex of working conditions where an accident occurred - the technological process, workplace, equipment, means of protection, etc. The monographic method allows us to identify not only the true causes of the accidents that have occurred, but also the causes that can lead to injuries, those. predict the level of injuries in a particular production.

Regulations on the investigation and recording of industrial accidents .

Investigation and recording of accidents is carried out in accordance with the "Regulations on Investigation and Accounting of Occupational Accidents and Occupational Diseases".

Accidents, occurred with the employee on the territory of the enterprise, when delivered to work or from work by service vehicles, while performing job assignments outside the territory of the enterprise, are considered to be related to production.

Accidents, occurred when using vehicles and manufacturing of any products without the permission of the administration, while stealing materials, tools, as a result of drunkenness of the employee, are considered not related to production.

Investigations are subject to accidents that occurred:

at performance of labor duties, and also at fulfillment of any actions under the instruction of the employer;

On the way to work or from work on the transport of the employer;

On the territory of the enterprise or in another place of work during working hours, including the established break;

In case of accidents at production facilities, equipment;

With an employee whose activity is related to movement between service facilities, during working hours on public transport or along the way following on foot, as well as during the journey to the place of work on the instructions of the employer;

During working hours by private transport, if there is an order of the employer for the right to use it for business trips or on behalf of the employer.

All those accidents that caused disability for a period of not less than one day, and as a result of which the victim is transferred to an easier job in accordance with the medical report, are subject to investigation.

The investigation of the accident is carried out within a period of not more than three days by a commission consisting of an authorized representative of the enterprise with the participation of a representative of the trade union, a worker of the labor protection service or the person responsible for these duties, other specialists.

After the completion of the investigation, the authorized representative of the employer with the participation of the above-mentioned persons draws up the Act on the accident at the production of FN-1 in 3 copies and is sent to the injured person, the state labor inspector, the occupational safety specialist at the enterprise.

On the non-productive accident, the act of FN is formalized.

The act is stored at the enterprise for 45 years, since the consequences of a certain injury can appear after a while.

A special investigation and record are subject to severe, group and fatal accidents that are investigated by the state labor inspector with the participation of the authorized representatives of the employer, the trade union, the higher management body.

The tenant reviews the documents of the investigation within 2 days after the end of the investigation, approves the acts of FN-1 and FN-P and registers it in the Journal of Registration of Industrial Accidents or in the Register of Non-Industrial Accidents.

TOPIC: 5 SYSTEM "MAN-MACHINE". CLASSIFICATION OF ERGONOMIC FACTORS. ORGANIZATION OF WORKPLACE, CONSIDERING SAFETY AND PRODUCTIVITY OF LABOR.

Work experienceis one of the forms of human activity aimed at transforming the natural world and creating material goods. In the structure of labor activity there are:

1) deliberately directedspruce - the production of certain products, the processing of natural materials, the creation of machines and mechanisms, and much more;

2) objects of labor- those materials (metal, clay), the transformation of which is aimed at people's activities;

means of labor- all devices, devices, mechanisms, adaptations by means of which objects of labor are transformed;

used technologies- methods and methods used in the production process.

To characterize the work activity, the following parameters are usually used:

1) labor productivity- the number of products produced per unit of time;

2) labor efficiency- the ratio of material and labor costs, on the one hand, and the results obtained on the other;

3) level of division of labor- distribution of specific production functions among participants in the labor process.

Influence of working conditions on the functional state of the human body and its performance .

Among the measures aimed at creating rational conditions for the production process, the working and rest regime of the worker plays an important role. All violations of the labor regime during the working day lead to a decrease in working capacity and rapid fatigue. Rhythmic labor is less tiring and provides greater worker safety. During the working day the working capacity of a person does not immediately reach its highest sustainable value.

Working capacityis the ability of a person to perform certain work qualitatively and productively in the shortest possible time.

The principal condition for improving the operability is:

1. in any work to enter gradually;

2. planned work;

3. rational mode of work and rest;

4. The attitude of the collective to work;

5. The uniformity and rhythm of work, which are selected individually.

Human performance depends on his health and working environment, on the organization of work and the nature of the production process, on qualifications and production experience, on the age and length of service, on individual characteristics. A great influence on a person's working capacity is provided by his conviction in the social necessity of labor and personal interest.

Working hours before and after the lunch break on the level of efficiency are divided into three periods:

period of workability;

period of stable working capacity;

period of reduced performance.

The first period lasts 30-60 minutes after the start of work. Having reached a certain accuracy and speed of movement, a person begins to work with maximum efficiency (the second period comes). Then gradually, as a consequence of coming fatigue, labor productivity falls (the third period). After lunch break, working capacity again increases to the optimal level and also gradually decreases by the end of the work day. Doctors, physiologists noticed that often the last 30-40 minutes you can see an increase in efficiency, which they defined as a "final impulse", the strain of the person completing his work day. Fatigue of a completely healthy person and a temporary decrease in his working capacity is a natural physiological process. To restore the working capacity of a person, he needs conditions for a normal rest. For a manual worker, rest should be calm. After mental work, an active rest is more expedient.

Ergonomic basis of safety

One of the sciences, the results of which are used to ensure the safety of life, is ergonomics, which teaches human capabilities in the process of various forms of activity with the aim of achieving maximum efficiency and the most favorable (comfortable) working conditions by combining the characteristics of a person and the environment.

In particular, in the "man-machine" system, ergonomics considers the problems of adapting technology to man.

The successful functioning of this system is possible if at least five of the following types of compatibility are provided: information, biophysics, energy, space-anthropometric and technical-aesthetic.

Information Compatibilityconsists in providing such information model of the device (machine) - information display devices (SOI) and sensorimotor devices (controls - levers, handles, buttons, switches, etc.), which would reflect all the necessary characteristics of the machine at the moment and allow the operator is unerringly receiving and processing information in accordance with his psychophysiological capabilities (features of attention, concepts, etc.).

The successful solution of this problem contributes to the operator's safety, improves accuracy, quality, and productivity.

Biophysical compatibilityassumes the creation of parameters (characteristics) of the environment (noise levels, vibration, lighting, microclimate, etc.), corresponding to regulatory documents and ensuring an acceptable operability and a normal physiological state of the operator.

Energy compatibilityprovides for the coordination of the applied effort, the power expended, the speed and accuracy of the movements of the controls of the machine (equipment) with the optimum capabilities of the operator.

Spatial-anthropometric compatibilityrequires the consideration of the size of the human body, its ability to review the external space, the working position (posture) in the design of the workplace (determining the reach zone for the operator's limbs, choosing the dimensions and design of the desk, seat, operator distance to the instrument console, etc.) .

Technical and aesthetic compatibilityis to ensure the satisfaction of the person from communicating with the machine, from the labor process, through the elegant execution of the device or device, its design.

General ergonomic requirements for the organization of workplaces .

The workplace is the place of permanent or temporary stay working in the process of work.

It should be organized in such a way as to create maximum comfort (comfortable conditions) for the worker and not to disrupt the technological processes.

The following ergonomic requirements are imposed on the workplace:

Sufficient working space, allowing the working person to carry out the necessary movements and movement during work;

Sufficient physical, visual and auditory connections between people in the process of work, between the working person and the equipment;

Optimal placement of the workplace in production premises;

Necessary natural and artificial lighting;

Permissible level of noise and vibration generated by equipment or other source;

Availability of necessary means of protection for workers.

The design of the workplace should ensure the speed, safety, simplicity and cost-effectiveness of maintenance in normal and emergency conditions, fully meet the functional requirements and expected operating conditions.

One of the most important industrial issues is the illumination of everyone in the enterprise. Thanks to this, comfortable working conditions are created, and thus the productivity of labor is increased. Insufficient lighting will have a bad effect on the person's vision, as well as lower the quality of the finished material. In such conditions, people notice things poorly and can not navigate the situation. And since the implementation of more complex tasks requires concentration, the visual apparatus undergoes high loads. Incorrect industrial lighting can even lead to the occurrence of traumatic situations.

General information

To the worker saw different objects on the surface, you need to get rid of the glitter.

This is a feature of the object to reflect the rays when light hits it. Such glare can cause irritability, as well as worsen visibility. To get rid of them, you should reduce the brightness of the lighting device or put it at a different angle. In warehouses, this problem is often not taken into account, using shiny structural profiles.

Sometimes there are interruptions to the voltage, resulting in a flicker. It not only irritates the worker, but also harms the visual apparatus. This can be avoided by means of special electrical circuits that stabilize the voltage drops.

Conclusion

If the requirements for lighting are met, then optimal working conditions are created, productivity increases, the probability of injuries and accidents is reduced. In addition, the pressure on the visual apparatus is reduced. In the reverse situation, different (eg nearsightedness) may occur. If the employee clearly sees the details, the work will be performed much faster.

To ensure the work of the entire production department, it is necessary to install additional sources of artificial lighting, starting from the work surface and ending. Only in this case the maximum safety of work in the production is achieved, and, accordingly, its effectiveness will increase.

So, we found out what kinds of lighting exist.

Requirements for lighting, are to ensure sufficient illumination of working surfaces, high quality and reliability of lighting installations, ease of maintenance and operation. In this case, the requirements of fire and electrical safety must be taken into account. Today, let's talk only about the requirements for lighting.

One of the factors of the external environment that determine favorable working conditions is the rational lighting of the working area. Insufficient lighting is one of the reasons for the decline in labor productivity and the emergence of occupational diseases of the visual apparatus.

Lighting is divided into:

- natural - the lighting of rooms with the light of the sky, penetrating through the light apertures in the outer enclosing structures

- artificial - lighting of premises with artificial light by means of electric lamps

- combined - lighting, in which insufficient natural light is supplemented by artificial

Types of indoor lighting:

- one-sided lateral (light apertures in walls) - light apertures are located in one of external walls

- bilateral lateral (light apertures in walls) - light apertures are located in two opposite walls

- top - light apertures are located in the upper floors

- combined - a combination of top and side natural lighting

The amount of illumination in the room from the natural light of the sky depends on the time of the year, the time of day, the presence of clouds, and the proportion of light from the sky that penetrates into the room.

The proportion of the light flux depends on:

- from the size of the light apertures (windows, light lanterns)

- light transmittance of glasses (strongly depends on the contamination of the glasses)

- presence of lightways in buildings, vegetation

- the coefficients of reflection of walls and ceiling of the room (in rooms with a lighter color, natural illumination is better), etc.

Natural light is better in its spectral composition than the artificial light created by any light sources. In addition, the better the natural lighting in the room, the less time you have to use artificial light, and this leads to the saving of electrical energy. With a lack of light from natural light, artificial lighting is used, created by electric light sources.

Kinds of artificial illumination of premises:

- working - lighting of premises, buildings, as well as areas of open spaces intended for work, people passage and traffic

- duty - lighting after hours

- emergency lighting for the evacuation of people from the premises during emergency shutdown of working lights

- evacuation - lighting for the evacuation of people from the premises in case of emergency disconnection of working lights, in the aisles, on the stairs, in the places of work outside the buildings or in the premises.

Work lighting is designed to ensure the normal performance of the production process, people's passage, traffic and is mandatory for all production facilities. Working illumination is arranged in all rooms and creates normalized illumination on working surfaces.

For standby lighting, use safety lighting fixtures or a part of the work lamps, powered by a separate group line. For lighting security, it is recommended to use a part of the general lighting fixtures. To illuminate emergency and safety (evacuation), incandescent or luminescent lamps should be used provided that lamps are supplied in all AC modes with a voltage of at least 90% of the rated voltage. Emergency lighting and safety should be sufficiently reserved due to a rational choice of the power scheme, especially if it can be carried out at a minimum cost.

Emergency lighting is arranged to continue working with emergency shutdown of working lights. For emergency lighting, incandescent lamps are used, for which self-powered electricity is used. The luminaires function all the time or automatically turn on when the working lights turn off unexpectedly. The minimum illumination of working surfaces in case of emergency lighting should be 5% of the normalized working illumination illumination, but not less than 2 lux.

Requirements for lighting, special lighting requirements

- Evacuation lighting is designed to evacuate people from the room when emergency shutdown of working lights. For the evacuation of people, the level of equipping the main passages and emergency exits should not be less than 0.5 lx at the field level and 0.2 lx in open areas.

- Security lighting is arranged along the boundaries of the territories protected by special personnel. The lowest illumination at night is 0.5 lux.

- Signal lighting is used to fix the boundaries of hazardous areas. It indicates the presence of danger, or a safe escape route.

Security lighting (emergency for evacuation) should be arranged: in the main passageways, corridors and on the stairs, used to evacuate people from buildings where more than 50 people work or stay simultaneously; also from health centers, books and archives, regardless of the number of people staying there; assembly halls, dressing rooms, in rooms where more than 100 people can be at the same time. (large auditoriums, dining rooms, assembly halls, conference rooms).

Security lighting should provide illumination of at least 0.5 lux on the floor of the main passages and on the steps of the stairs. In the office buildings, you should set the "Exit" light signs at the exits from the dining and assembly halls, conference rooms and other rooms intended for simultaneous stay more than 100 people; Exits from the corridors, which are adjacent to the premises, where at the same time there may be more than 50 people; Exits from the stage of conference halls and assembly halls, along corridors with a length of more than 25 m. The signposts "Exit" must be connected to the safety lighting network (evacuation), and the light indications with built-in autonomous power sources - connected to the working lighting network and automatically switched on an autonomous power supply in case of emergency extinction of working light.

According to its design, artificial lighting can be:

In the case of general uniform illumination, all spaces in the room receive light from a common lighting installation. In this system, the light sources are evenly distributed without regard to the location of the workplaces. The average level of illumination should be equal to the level of illumination required for the performance of the forthcoming work. Systems are mainly used in areas where jobs are not permanent.

The system must meet the requirements:

- is equipped with anti-glare devices (grids, diffusers, reflectors, etc.)

- part of the light should be directed to the ceiling and the top of the walls

- the light sources should be installed as high as possible to minimize glare and make the lighting as uniform as possible

A generalized localized lighting system is designed to increase lighting by placing lamps closer to the working surfaces. Lamps under such lighting often give highlights, and their reflectors should be positioned in such a way that they remove the light source from the direct field of view of the worker. For example, they can be directed upwards.

Combined lighting along with the general includes local lighting (a local lamp, for example a table lamp), which concentrates the light flux directly at the workplace. The use of local lighting in conjunction with the general is recommended for high lighting requirements. The use of one local lighting is unacceptable, since there is a need for frequent adaptation of vision, deep and rare shadows and other unfavorable factors are created. Therefore, the share of total lighting in the combined should be at least 10% (for rooms that have natural lighting).

Combined lighting

Requirements for lighting, combined lighting of the room

In addition to natural and artificial lighting, their combination can be used, when the illumination due to natural light is not enough to perform a particular job. Such lighting is called combined. To perform the work of the highest, very high and high accuracy, combined lighting is mainly used, since, as a rule, natural illumination is not enough.

Illuminance in the workplace should correspond to the nature of the visual work, which is determined by the following parameters:

- There should be no sharp shadows in the workplace.

- Ensure a constant light in the workplace in time.

- Absence of direct and reflected brilliance in the field of view.

- Rational direction of the light flux.

- Provide the necessary spectral composition.

- Safety and ease of use.

- Natural and artificial lighting in the premises is regulated by the norms, depending on the nature of the visual work, the system and the type of lighting, background, and the contrast of the object with the background.

In production and administrative-public premises, in cases of primary work with documents, a combined lighting system is allowed (general lighting fixtures are also installed for general illumination intended to illuminate the location of documents). Illumination on the table surface in the working document placement area should be 300-500 LC.

See also on this topic.

The standards of room illumination are an indicator that is very important for effective production. Their observance helps to reduce the amount of rejects and, accordingly, increase productivity (according to calculations, qualitative lighting can increase this figure by 10%) and product quality. In addition, compliance with these standards is important for the normal well-being of employees, which positively affects their performance, and therefore, on the productivity of their work. Also, due to insufficient illumination, you may encounter a problem of injuries in the workplace.

Observance of the norms of illumination implies ensuring it at a sufficient level in each of the workplaces.

Do not think that in this case we are talking only about artificial lighting. In production rooms, three types of lighting are used.

- The first is natural illumination due to sunlight and reflected from the sky or diffuse light. In turn, natural light can enter the room through openings in the area of the roof of the building (in this case it is called the top one), through windows (this is side lighting) or both ways at once (such lighting is called combined). Natural lighting is certainly the most pleasant and useful for the eyes of employees, but its lack is its instability, dependence on the time of day, weather, season.

- In production, it is impossible to do without a second type of lighting - artificial. For him, different types of lamps can be used. In addition, in production, as a rule, there are several different lighting systems: used for work or for building protection, emergency, on duty.

- Most often today in the production premises is used a combination of artificial and natural lighting, which is called - combined.

When calculating lighting for production, the following requirements should be considered:

And of course, all lighting equipment must meet the requirements and safety standards, be properly and regularly undergo appropriate checks.

To estimate the level of illumination in numerical values, an indicator is used that characterizes the illumination of 1 meter square with one lumen - this is lux (LC). In addition, it is worthwhile to know such a designation as KEO (natural lightness coefficient). This coefficient differs depending on the nature of the work: the higher their accuracy and the more "shallow" work, the higher the coefficient.

Standards of illumination of industrial premises table

As you can see, in the norms there are 4 main groups: group a is the level of illumination at constant work, b - when the staff is in the room constantly, but the work is performed by periods, c - periodic not only work, but also finding workers in this room, g - lighting to control the production processes.

There are also certain standards for office space.

When calculating and installing production lighting, do not forget that it must correspond to a sufficiently large list of requirements: naturally, the first is full compliance with all standards. In addition, it is worth taking care of the reliability of the lighting and security system for employees. In industrial buildings, as elsewhere, the stability of the lighting system is important to mechanical influences, vibrations. Also many owners of manufactures today seriously puzzled the question. In this case, it is worth choosing for the equipment of production is not standard incandescent lamps, but more expensive, but paying off in a long period, options: it can be either. In addition, to save energy in the passageways, you can equip the lighting system with motion sensors.

Example of calculation of illumination of industrial premises

To calculate the artificial illumination of industrial premises, three main methods are used: the method of setting the specific power, the point method and the coefficient of use of the light flux.

To calculate the coefficient of light flux, the area of the room and the area of all horizontal surfaces reflecting light are taken into account.

The method of specific power does not give exact values, it is used most often for documents, surveys, preliminary estimates of the cost of the lighting system. A more accurate method is the point method. It is used when there are direct light sources in the room. In this case, the degree of illumination at each point and for each of the light sources is calculated. The technique itself is considered to be quite laborious, but at the same time very accurate.

To calculate the lighting of the room, several actions should be taken: first, choose the lighting system; second, calculate the illumination standards for each workplace, taking into account the unevenness of the lighting. Also, you should consider whether there are reflective surfaces in the room. In what color are the walls and ceiling painted. After this, the index of the room is calculated and the number of lamps necessary for it. All received data are plotted on the drawing.

Related materials:

LIGHTING OF INDUSTRIAL PREMISES

Influence of lighting conditions on performance, safety and productivity

Light is a natural condition of human life, playing an important role in maintaining health and high efficiency. It has a positive effect on a person's emotional state, metabolism, cardiovascular and central nervous system.

The visual analyzer of the person is the main source of the information received by him about the external world.

Thus, being an important indicator of occupational health, industrial lighting is designed for:

Improvement of the conditions of visual work and reducing fatigue;

Increase of labor safety and reduction of occupational diseases;

Increase of labor productivity and quality of products.

Light is part of the electromagnetic spectrum of visible radiation (λ = 0.38-0.77 μm).

Basic lighting values and measurement units

Light engineering quantities quantify the effect of light radiation on the human eye. Usually, quantitative indicators such as luminous flux, luminous intensity, illumination, surface brightness, reflection, transmittance and absorption coefficients are used.

luminous flux (F) - the radiation flux estimated by its impact on people. eye.Za unit - LUMEN (lm)

intensity of light (I) - spatial density of light flux, cat. determine the ratio of the light flux F to the body (spatial) ω, in the cat. it spreads. For the unit of luminous intensity accepted candela (cd). The solid angle is part of the space of the sphere, bounded by a cone reflected on the surface of the sphere, with the vertex at its center. The unit of solid angle is steradian (cp).

illumination (E) is the surface density of the light flux F. With a uniform distribution of the light flux perpendicular to the illuminated surface S, the illumination  . Measured in lux (lux)

. Measured in lux (lux)

the brightness of the surface (B) - is the surface density of the force of light and is defined as the ratio of the strength of the light I in a given direction to the projection of the luminous surface on a plane perpendicular to the direction of observation.  , where ά is the angle between the normal to the surface S and the direction to the eye. Per unit. brightness candela per m 2 (cd / m 2

).

Brightness is light. value, the cat. directly perceives the eye people. Visual sensations are determined by the brightness of the illuminated surface, depending on its color, roughness, and other factors. Excessive brightness causes short-term fading

, where ά is the angle between the normal to the surface S and the direction to the eye. Per unit. brightness candela per m 2 (cd / m 2

).

Brightness is light. value, the cat. directly perceives the eye people. Visual sensations are determined by the brightness of the illuminated surface, depending on its color, roughness, and other factors. Excessive brightness causes short-term fading

reflection coefficients ρ, transmittance τ and absorption β of surfaces are measured in% or fractions of unity.

,

,

,

, , where F ρ, Fτ, F β are respectively reflected, absorbed and transmitted through the surface light streams

, where F ρ, Fτ, F β are respectively reflected, absorbed and transmitted through the surface light streams

FON is the surface. directly adjacent to the object. The background is light at ρ\u003e 0.4, the average at 0.4\u003e ρ\u003e 0.2, dark at ρ<0,2

The contrast of the K-object of observation and the background is determined by the difference between their brightness

K = (Bo-Bf) / Bf, where B0 and Bf are the brightness of the object and the background

The effect of light on the human body

Light is one of the most important conditions for the existence of people. It affects the condition of the body. Correctly organized lighting stimulates the processes of nervous activity and increases efficiency. When there is insufficient lighting, people. works less productive, quickly becomes tired, the probability of side effects increases, which can lead to injuries. It is believed that 5% of injuries can be the cause of such prof. diseases like working myopia (nearsightedness)

Depending on the wavelength, the light can exert an exciting (orange-red) or calming (yellow-green) effect.

The spectral composition of light affects the productivity of labor. Studies show that if the production of people. under natural light take for 100%, then with red and orange lighting it is only 76%. In humans, the cat. for some reason, partially or completely deprived of natural light, light starvation may occur. With good lighting eliminates eye strain, accelerates the pace of work.

Natural and artificial lighting, their sources, rationing.

Kinds and systems of illumination

Depending on the light sources, industrial lighting can be natural, artificial and combined.

Natural lighting in the room can be formed by direct sunlight, scattered light of the sky and reflected light of the earth and other objects.

Artificial lighting is created by incandescent lamps or gas-discharge lamps.

Combined lighting is an addition of natural lighting artificial in the dark and light time of day with insufficient natural light.

The natural light in its spectral composition is significantly different from artificial light.

In the spectrum of sunlight, there are much more than the ultraviolet rays necessary for man, it is characterized by high diffuseness (scatteredness) of light, which is very favorable for visual working conditions. Natural lighting provides visual contact with the external environment, eliminates the monotony of the lighting situation in the rooms, causing premature fatigue of the nervous system.

Considering the high biological and hygienic value and positive psychological impact of natural light, in practice they strive for the maximum possible use of it in the design of industrial lighting.

Premises with a permanent stay of people should, as a rule, have natural light.

By design features daylight it happens: lateral, when light penetrates into the room through the light apertures in the outer walls, windows; upper - through the upper light apertures, lanterns; combined - a combination of side and top lighting.

Since the level of natural light can change dramatically in a short time, the normalized value (quantitative characteristic) of natural light is not the illumination of the workplace, but the coefficient of natural light (KEO).

The natural light factor (e) is the ratio of natural illumination at a reference point inside the room (  Ev) to the simultaneous value of the external horizontal illumination (En), created by the light of a full open sky.

Ev) to the simultaneous value of the external horizontal illumination (En), created by the light of a full open sky.

KEO It shows what part of the external illumination is the illumination at a certain point inside the room

KEO (e) =  %

%

Artificial lighting for functional purposes is divided into working, emergency, evacuation, security and duty.

Work lighting is arranged in all rooms, as well as areas of open spaces intended for work, people's passage and traffic.

Artificial working lighting can be general and combined, when a local, concentrating light flux is directly added to the workplace. The use of one local lighting inside buildings is not allowed.

Depending on the location of the equipment and workplaces, the overall lighting can be uniform or localized.

Emergency lighting is provided in all cases where a sudden disconnection of the main lighting can cause an explosion, fire, people poisoning, the risk of injury, prolonged disruption of the process or malfunctioning, communication centers, water and gas supply installations, duty posts and control points for various systems.

Evacuation lighting is provided in the aisles of industrial buildings with a number of employees more than 50 people, where the exit of people from the room with sudden disconnection of working lights is associated with the danger of injury.

Security lighting is provided (in the absence of special technical means of protection) along the boundaries of the territory, protected at night.

The attendant turns on outside working hours.

Artificial lighting is estimated by the amount of illumination (E, lk).

The sources of artificial lighting can be incandescent and gas-discharge lamps.

The service life of incandescent lamps is up to 1000 hours, and light output from 7 to 20 lm / W. The greatest advantages are iodic incandescent lamps. They have a service life of 3000 hours, and a light output of up to 30 lm / W.

Visible radiation from incandescent lamps prevails in the yellow and red parts of the spectrum, which causes distortion of color reproduction, makes it difficult to distinguish the shades of colors.

Gas discharge lamps have light characteristics that more fully meet hygiene requirements. At them the radiation of the optical range of the spectrum arises as a result of an electric discharge in the atmosphere of inert gases, metal vapors and their salts. The service life of gas-discharge lamps reaches 14 000 h, and the light output - 100 lm / W.

By selecting inert gases and metal vapors in the atmosphere of which the discharge occurs, it is possible to obtain a light flux of gas-discharge lamps in any part of the spectrum.

In gas-discharge lamps, a balloon is filled with mercury vapor and an inert gas, a phosphor is applied to its inner surface.

The most common gas discharge lamps are low-pressure and luminescent lamps in the form of a cylindrical tube. They are produced in different colors: fluorescent lamps (LD); cold white color (LHB); white color (LB); Heat-white (LTB) and with improved color rendition (LDC).

fluorescent lamps are a glass tube, the inner surface of which is covered with a phosphor. The passage of Eltok through this mixture is accompanied by the emission of ultraviolet rays invisible to the eye, which cause the luminescence to glow. Thus. in fluorescent lamps, the electricity first turns into ultraviolet rays, and then, with the help of a phosphor, into visible light. Applying various phosphors can give the lamps a different color, including close to daylight.

fluorescent lamps have a small brightness and therefore do not have a blinding effect on the eyes, the surface of the lamp tube is slightly heated (40-50). The disadvantages of fluorescent lamps include the fact that for ignition and stabilization of the combustion mode, a special ballast is necessary, which complicates their operation and reduces the efficiency. Lighting from a fluorescent lamp can cause stroboscopic effect , which consists in the fact that, due to the absence of thermal inertia, the rotating parts of machines illuminated by a lamp may appear to be stationary or rotating in the opposite direction. This effect can be reduced by including neighboring lamps in different phases of the network, but it can not be completely deleted. The main disadvantage is the greater sensitivity to changes in ambient temperature. The normal mode of operation of the lamp is provided at ambient temperature of 18-25 ° C

High-pressure discharge lamps include metal halide, sodium, arc, mercury, xenon and others.

Mercury lamps, unlike luminescent lamps, light up steadily and work well both at high and low temperatures of the ambient air. They have a large capacity and are used mainly for lighting high industrial premises and streets.

Xenon lamps consist of a quartz tube filled with xenon gas. They are used to illuminate sports facilities, railway stations, construction sites. They are sources of ultraviolet rays, the effect of which can be dangerous when illuminated with more than 250 lux.

The most promising are halogen lamps, the discharge of which occurs in the vapor of halide salts, as well as sodium lamps. They are characterized by excellent color rendering and high efficiency (light output 110-130 lm / W).

With combined lighting, the general artificial lighting of rooms should be provided with gas-discharge lamps. The use of incandescent lamps is allowed in cases where, according to the conditions of technology, environment or requirements for interior design, the use of gas-discharge lamps is impossible or impractical.

Combined lighting is estimated by the natural light factor when disabling artificial light sources.

The norms of production lighting are set according to:

Characteristics of visual work (the smallest object size of discrimination, luminosity of the background, the contrast of the object with the background;

Discharge and sub-division of visual work;

Kinds and systems of illumination (for artificial illumination).

For the 1st: the object of discrimination is determined by the smallest size of the object (part) or part of it, which must be distinguished (learned) during the execution of this work (eg, point, wire thickness, etc.).

For the second: depending on the size of the object of discrimination and the distance of the object from the eyes of the worker, all works are divided into 8 digits of accuracy, which, in turn, are divided into sub-sections (a, b, c, d) depending on the contrast of the detail of discrimination background and the reflection coefficient of the background. For each subsection, the norms set a certain value of the illumination and natural light factor, which decrease as the size of the parts increases, the contrast with the background and the reflection coefficient (the background is the surface adjacent to the object of discrimination on which it is considered)

Requirements for lighting workplace

- Illumination in workplaces should correspond to the nature of visual work

A fairly even distribution of brightness for a slave. surfaces

Absence of sharp shadows on the slave. surfaces

Lack of glitter

Constancy of illumination in time

Correct color rendering

Provision of electrical, explosion and fire safety

Economy

Artificial light in its spectral composition should approximate the natural

The lighting of the working area must satisfy the trace. conditions:

Light level slave. surfaces must comply with the hygienic standards for this type of work

It should be ensured uniformity and stability of the level of illumination in the room, the absence of sharp contrasts between the illumination of the office. surface and environment. space

In the field of view, no light should be created by light sources, etc.

Artificial light in its spectral composition should approximate the natural

SUBJECT: 2 BODIES OF OVERSIGHT AND CONTROL OF COMPLIANCE WITH LABOR LAW. SYSTEM OF SAFETY STANDARDS OF LABOR

Supervisory bodies and control over observance of labor legislation in the Republic of Belarus .

Supervision and monitoring of compliance with labor legislation is carried out by specially authorized state bodies acting in accordance with the legislation.

The control is carried out on 3 levels:

State;

Public;