Effective management plays an important role in the heating unit. With the competent introduction of control parts into the boiler, it is possible to achieve energy savings, arrangement of a comfortable microclimate, to get rid of overheating or cooling the room. One of these automatic parts is the thermostat.

An automatic device that supports a given temperature is called a thermoregulator. In its design, a sensor can be integrated or it can be outside of it. The sensor captures information and transfers it to the area of the device itself, from where the command is transmitted to the information zone of the boiler, and the unit starts or stops.

There are devices with mechanical and programmatic control.

Purpose:

- Automate combustion processes and make the transfer of heat to the heating circuit.

- Coolant temperature control, premises.

- Prevent emergency jumps increase of heat.

Principle of operation

Principle of operation of the solid fuel boiler thermostat

The boiler sets the operating temperature of the coolant, when the temperature of the liquid falls, a certain signal is output and the unit turns on.

Using the thermostat makes it possible to control the room temperature. It incorporates a sensor that is located far from the heating structure, and reacts the device to the environment. The information received from the sensor is transmitted to the control of the unit, on the basis of which, it turns on or off.

At the first stage of the invention of thermostats, the connection of the two devices was conducted by means of wires. What can not be said about modern models, now work is remotely. The term devices monitor and regulate the consumption of energy resources, building temperatures, prevent overheating or subcooling.

Advantages and disadvantages

Pros:

- Increase the thermal comfort in the room.

- Saves energy consumption.

- Warning of an emergency in the heating circuit.

- Easy to connect.

- Easy maintenance.

- Wide range of models.

- Fuel economy.

Minuses:

- High price.

Kinds

Central

In this form, the temperature of the entire system is monitored. Installation of it is coordinated with the boiler. Special wires or other wireless transmission options are used. The element is powered from the mains, although there is some autonomy from the equipment. This type controls the heating of the boiler and the coolant. Devices are not used to adjust the individual rooms of one system, but perfectly keep the entire heating system in safety.

Local value

Unlike the previous type, this type can adjust the temperatures in individual rooms. The device is installed in accordance with the boiler. There are some requirements for their location: it can not be fastened near doors, boiler and windows, as this will distort the temperature data.

The presence of sensors makes it possible to monitor the expansion of the coolant, and due to this the temperature is regulated. The devices of this option can be connected to the boiler again, and if there is an emergency temperature of the circuit, the boiler will stop working and turn off.

For radiator

The temperature regulator controls the temperature of all radiators separate from each other. The radiator includes a valve to reduce and increase the flow of liquid or gas inside, and also a thermostat that regulates this procedure. In order for the device to work correctly, a hydraulic calculation is made for a particular heating system (forced or natural circulation, single or double circuit).

Room

Has the ability to program a certain mode. For example, it is possible to set the heating of the coolant at night, for a day, a cooler temperature. Its design includes sensors, and they must be placed in different places in the room. External factors should not influence them.

Models without programming have a simple scheme of work. The device has a small wheel, which sets the desired temperature in the building. As soon as its threshold is reached, the device will close the contacts, and the signal will be transmitted to the control part. The servo drive will execute any command to open or close a valve.

By type of functions, you can select:

- Devices with one operation, when only the temperature is maintained.

- Multioperational, where various functions are programmatically included.

For execution, for agreement with the boiler:

- Wireless.

- With wires.

The devices are installed in any convenient place, the temperature sensor is connected and connected to the control zone of the unit. The location of the indoor unit should not be covered, for example, with curtains, furniture.

It is desirable to contact with a constant supply of air, this will ensure the normal operation of the device. Another detail - the location of electrical appliances (televisions, lamps, etc.) nearby, is also undesirable.

Criterias of choice:

- Manufacturing of a thermostat and a boiler by one manufacturer.

- Manufacturer.

- Characteristics.

- Options.

Installation / Connection and Setup

When mounting a wired device to adjust the temperature, we choose not the solar portion of the room. We will mount the bracket on a length of 150 cm from the floor. There are terminals with letters COM and NO on the sensor, we are connecting a thin two-wire wire here, it must be connected to special terminals (for a thermostat) of the boiler.

The power supply will be a two-piece finger battery.

In the wireless type of wire we will not pull. The execution part is connected to the boiler, and the sensors are located at different points. Signal from the sensor is not afraid of concrete floors and other obstacles.

The device also operates on finger batteries.

You can install them not in one copy for different pumps, but several, just make the settings of the signals, so that everyone understands his team. The instruments are adjusted according to the attached instructions, since each view has an individual adjustment.

Price

The cost of production depends on the way of performance, manufacturer, brand, characteristics.

For example, the thermostat-programmer from Ariston costs 4000 rubles. The sensor of street temperature, Italian production - 1000 rubles.

How to make your own hands?

Thermoregulators, which are provided on the shelves of stores, have a reliable design, but people who are versed in electrical engineering try to make the device on their own.

To do this, you need to stock up the component parts, such as the digital display, the microcontroller and other elements, and start assembling the simplest circuit in the first stage. Only having received a positive result, it is possible to complicate the task.

Temperature control algorithm

We suggest you get acquainted with the circuit diagram of the device, which reflects the algorithm of the device. Here we see that an element is needed to measure the temperature and transfer the signal to the post-processing unit. The last element amplifies it and transmits the command of the relay, which serves as the executive element.

Let's consider the simplest scheme.

In order for the current to pass only in one direction, we use a zener diode, since it additionally has control contacts, in comparison with a simple diode.

To the element we supply voltage also in the open state, it will pass current. As soon as its value decreases to the lower limit, the chain will break. Logical control of the circuit is conducted here by a zener diode.

The circuit with a zener diode:

The circuit with a zener diode

We represent it in two parts. In the left part of the diagram we show the part preceding the control contact of the relay (K1). Thermal resistor (R4) is a measuring element. If the temperature rises in the environment, there will be a decrease in resistance.

The temperature can be adjusted manually, for this purpose we set up a variable resistor R1 in the circuit.

The circuit is powered by a voltage of 12 V. In a closed circuit, with the relay on, the zener diode control contacts will have a voltage of 2.5 V.

As a power supply you can use any inexpensive device.

The relay is better to take a reed switch, for example, RES47 or RES55A. Thermal resistor can be models MMT, KMT or similar.

The principle of the circuit is as follows: the temperature is set to a certain limit and when it rises above the threshold, at element R4, a drop in resistance and voltage (less than 2.5 V) occurs and the circuit breaks.

Synchronously, the power part will be disconnected by the resistance in the right part of the circuit. The thermal relay, supplied, D2, executes the role of the executive unit and the voltage on it is 220 V.

The temperature controller is an irreplaceable thing for an individual heating system. It not only saves gas, but also makes your life more comfortable. A very pleasant combination of qualities, is not it? I hope my story will convince you to start using it.

Why you need a room thermostat

It would seem, why complicate the circuit and cling an additional device? After all, any heating boiler has its own temperature regulator. In simple models, this is a mechanical krutilka with figures 1, 2, 3 ... In boilers more expensive is the more modern automation, allowing you to set the temperature to within one degree. However, in both cases it is a question of temperature (water in the heating system), rather than air. Than it is bad?

As an example, take my "treshka" in an ordinary Khrushchevka, where two windows face north and two - to the south. What happens on a clear day? Even in the winter, the sun senses warmly the southern rooms, and near the window it all becomes hot. The natural way of heat spreads to most of the apartment and the need for the heating is turned off for a few hours.

All this time, the gas boiler, located on the north side, continues to operate. After all, the heat does not reach there, and the water in the circuit cools quickly enough, allowing the boiler to turn on. Since there is little water in the heating system, it heats up quickly and then turns off again.

Thus, the operation of the boiler without a room thermostat looked like this: I switched on, worked for 2-3 minutes, disconnected, switched on again after 10-15 minutes. Needless to say, this regime has a negative impact on both gas saving and the resource of the boiler itself. Therefore, several years ago,

Mechanical thermostat for boiler

The simplest device, which is a small box with a built-in sensor and a temperature regulator. Connecting the room thermostat to the boiler automatically changes the operating mode. Now it depends not on the water in the circuit, but on the ambient air, which cools down much more slowly.

Having set a comfortable temperature on the thermostat, you can forget about its existence. The boiler will turn on much less often, which saves you gas and, accordingly, money. Leaving for a long time from home or leaving for a few days, you can put on 15-18 degrees, which will further reduce consumption.

The simplest model costs from $ 15 and saves you this amount for an incomplete season. Comparing the consumption "before" and "after", it turned out that the savings amounted to about 15-20%. Before the installation of the thermostat, at least 200 cubic meters of gas were consumed, after it was no more than 170.

The device suited everyone, except, perhaps, appearance, which did not fit into the views of his wife about modern design. Therefore, last year it was replaced

Programmable thermostat for heating system

Performing the same functions as a mechanical thermostat, the programmer has a number of additional "buns".

Among the shortcomings can be noted a higher price (from $ 30) and the need for periodic replacement of batteries.

After spending a few days studying the possibilities of the device and experiments, I settled on the following scheme for everyday life:

from 00.00 to 06.00 - 19 ° C

from 06.00 to 08.00 - 21 ° C

from 08.00 to 17.00 - 18 ° C

from 17.00 to 22.00 - 21 ° C

from 22.00 to 00.00 - 19 ° C

On the output, the temperature controller operates in a different mode:

from 00.00 to 07.00 - 19 ° C

from 07.00 to 22.00 - 21 ° C

from 22.00 to 00.00 - 19 ° C

The result I was simply overwhelmingly happy, and even surprised a little. In total, the time of "clean" boiler operation was reduced to 2-4 hours per day. It's in the cold. At a plus temperature, heating may not be switched on for a day or even more. Despite the fact that all windows are practically open around the clock for micro-ventilation, the temperature in the apartment does not fall below 21 ° C.

The gas consumption has broken all previous records and now extremely rarely exceeds 150 cubes. For the sake of justice, I note that it is hardly a merit of a thermostat alone. Simultaneously with its installation, insulation works and replacement of insulating glass units with energy-saving ones were carried out. Of course, this affected the reduction of heat loss.

What I can say for sure is that the programmer, combined with the warming, gives stunning results. Using a thermostat for a heating boiler, you can achieve maximum efficiency of the entire system and save a lot of money.

Solid fuel heating boiler is an option for those who want to have an autonomous, inexpensive heating system in their home that is independent of gas supply and electricity. The main thing is to stock up with wood, coal, wood pellets, sawdust and other solid combustion products, on which the boiler will work. And thanks to the process of prolonged burning of solid fuel, the temperature in the house will always be necessary, and, to control and regulate the temperature in the house, of course, a thermoregulator will be needed.

Types of boilers and the need for temperature controllers

In this type of heating system, cast iron and steel boilers. Both have both positive and negative characteristics. For example, steel has a high heat output, rapid heating and a relatively low price. But they can be exposed to the external environment. Then, during corrosion or clogging, the entire heat system may deteriorate. To prevent this, it is necessary control the temperature in the boiler and adjust the temperature regimes.

On the contrary, cast-iron ones have high strength, practically do not give in to corrosion and influence of an environment, reliable and stable in operation, keep heat for a long time, consist of easily replaced sections. But boilers of long burning of solid fuel, according to experts, can fail only in the case of sudden temperature changes. Therefore, when installing such a boiler, it is necessary to correctly and professionally bundle the boiler. And, of course, you need to constantly monitor the temperature regime and adjust it as needed.

If you believe the specialists, when using the thermostat 15-20% of fuel is saved, the heat is stored in the required parameters, if necessary, the entire heating system is switched on or off.

The difference between thermostat and thermostat

The thermostat is already in the heater system and is responsible for the operation of the coolant. This is a mechanical device, which is usually. Its plus - you can constantly monitor the temperature regime in the coolant, this process does not depend on the availability of electricity in the house. Minus - adjust the temperature manually.

The thermostat is already in the heater system and is responsible for the operation of the coolant. This is a mechanical device, which is usually. Its plus - you can constantly monitor the temperature regime in the coolant, this process does not depend on the availability of electricity in the house. Minus - adjust the temperature manually.

Thermostat - separately mounted mechanism, which automatically monitors the temperature of the coolant, premises, controls it, regulates the correct heat supply. And does it all within 24 hours automatically, without user intervention.

Nuances of use

Thermostats for solid fuel boilers must be set to average temperature in the house +20 degrees Celsius. But there are nuances:

- In the children's room, the temperature is preferred +22.

- In a room where elderly people live, people with disabilities +23.

- In the case of living hypertensive patients it is better to keep the lower temperature regime + 18, + 19.

- At night, it is recommended + 19, + 21.

Types of temperature regulators

The choice of temperature controllers is huge - from mechanical thermostats to programmable ones, on a microprocessor-based basis.

- So called room controllers are installed in any room and react to the temperature in it. The main thing when installing - do not cover the appliances with furniture, curtains, any objects. Then the indicators may not coincide with reality, and the whole system will fail.

- The valve device regulator is tied to a specific fuel line and controls the temperature regime not of the boiler, but of the section in a certain place, where a valve installed in the pipe is installed.

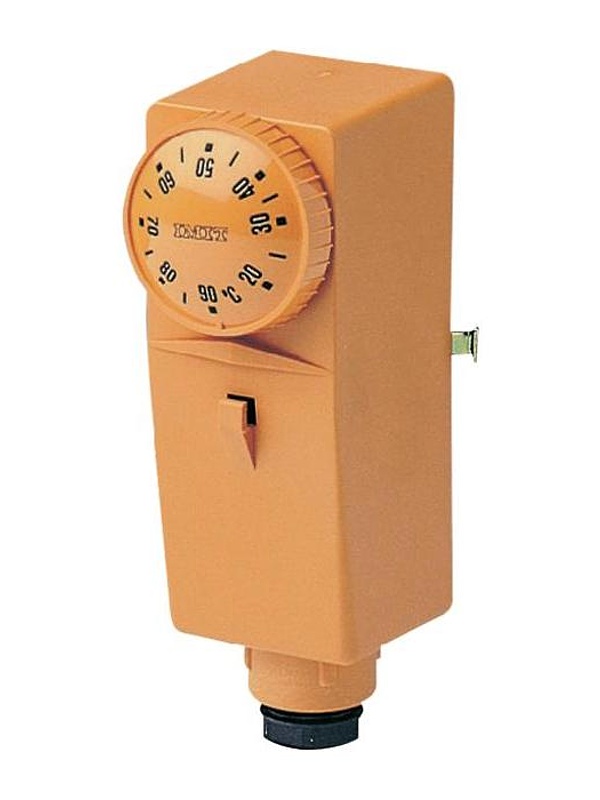

- Automatic cylinder thermostat - the simplest device for a two-chamber conventional boiler. This device is installed on the boiler, it is programmed, as a rule, only at the maximum temperature and causes the boiler to shut down when the temperature of the heating element exceeds the programmed temperature.

- Zone regulators - are programmed to a certain area of the room and prevent not only the shutdown or high temperature, but also report all the indicators that the consumer needs to know.

In addition, all thermostats are divided into:

- Wired.

- Remote.

The main criterion for selection is ease of installation. It is also necessary to take into account that the boiler and the thermostat were compatible. To do this, you need to buy all the equipment of one manufacturer or seek the help of specialists.

Automation of heating equipment is used for the convenience of management, economical consumption of energy resources. To correctly use the thermostat for a heating boiler (temperature controller), modern engineering solutions must be studied. Useful review of the current market situation. It is also necessary to assess the possibility of performing assembly operations independently, without resorting to expensive professional services.

Why do I need a thermostat for a heating boiler (temperature regulator) in rooms

When developing new heating equipment, great attention is paid to the efficiency of the use of energy resources:

- Electric heaters are designed in such a way that the formation of useful infrared radiation occurs with the maximum efficiency.

- In the establish a system of constant flame control, which optimize the combustion process.

- When using solid fuels, complex chambers are created on the way to the output of the combustion products. Here the temperature increases additionally.

But the rational use of electricity and fuel will be useless, if the optimal flow of created heat is not ensured. To solve such a problem you need certain parameters of individual components.

For the latter, the condition is required for the heating boiler (temperature regulator). With proper application of this technique, you can get at your disposal the following advantages:

- Maintaining the set temperature in automatic mode, without the need for careful monitoring.

- Savings of energy resources (cash) up to 30% or more.

- Possibility of remote control, fast transition to special modes.

- Extension of the service life of the boilers due to careful operation.

For your information! Optimizing the operation of the equipment with a thermal sensor for the heating boiler will extend the battery life when the mains is disconnected. From the built-in battery the technician will work for a long time, which will increase the time for calling specialists, eliminating the emergency situation.

Functions of the temperature sensor for the boiler: adjustment of the coolant temperature

Typical gas equipment works as follows. Burners heat the coolant to the desired level. It is not a constant. In systems, the temperature does not exceed + 40 ° C. It is raised to + 50 ° C and above. A special pump is used to circulate the fluid along the contour. Once the temperature has reached the desired level, the flame goes out. When the coolant cools down, the heating starts up again.

This scheme of work is characterized by the following features:

- The burner ignites quite often for a short time. It runs for about 2-3 minutes during one cycle lasting from 5 to 15 minutes.

- As a rule, the circulation pump is switched on continuously.

- When changing weather conditions and indoor temperature, the user must reconfigure the equipment.

The cost of such a thermostat for a heating boiler (mechanical) is not great, but the final price of such a solution will be high. The situation will not change radically, if we use state-of-the-art electronics. In this case, the problem is created by the principle itself - control of secondary parameters. The temperature of the incoming liquid, and not the parameters in the room, is checked, therefore corresponding errors appear, the inertia increases.

Control of temperature regimes inside and outside the premises

It would be more reasonable to move the measuring instruments to a residential area. If you install the sensors here, it is easier to optimize the operation of the boiler. But not all models of technology are designed for such connections. In some cases, modernization with the use of original products of the manufacturer is too expensive.

To solve the problem with reasonable costs, it is useful to purchase and install a remote room thermostat for a gas boiler.

The modern boiler control system consists of several parts:

- In this version, the room temperature sensor and the outdoor air are connected directly to the thermostat.

- Power is provided by the AC adapter. Built-in rechargeable batteries ensure that the battery remains operational when the 220V is disconnected.

- For remote control, a GSM unit is installed here. With its help, the user will receive operational data on the temperature inside the premises. If desired - it turns on the desired mode by sending a control signal from the smartphone, tablet. This function is performed under the control of specialized software.

- The commands to the boiler come through a wired connection. They include heating and a pump. This is more economical than the built-in thermostat, discussed above. The air temperature decreases more slowly than the coolant, so the burner ignition frequency decreases. In such conditions, the service life of the equipment is extended.

Important! In compatible with the room thermostats, the boilers on the control board must have special "Room Thermostat" input sockets. The corresponding possibilities are indicated in the official instructions of the manufacturer.

The algorithm for the operation of such equipment in the complex deserves high marks. If the sun came out, the temperature on the street rose, the boiler would not turn on. It became colder in the room after airing - there is no need to reconfigure the technique for heating and then set the regulators to the normal position. The necessary actions will be performed automatically. Just one season you can recoup the investment made. But in any case, a more thorough study of the parameters of equipment and models presented on the market is useful.

In order to choose the right equipment, we need to consider the need for outdoor temperature sensors. In some boiler models, they are connected directly to the standard electronic control board. With their help optimize the parameters of inertial processes.

So if the user has set the temperature too high and the outside is warmer, the batteries will continue to heat up even when the boiler is turned off by the thermostat. If there are sensors outside the room, the required command will be given faster. The actual savings in the process of their active use are low. Therefore, these advanced capabilities are evaluated in conjunction with a certain increase in cost.

Varieties of technology and selection criteria

Thermostats for heating boilers (temperature regulators) are equipped with various hardware and software units. The following are additional functionalities and technical features of modern models:

- Sensitivity of temperature adjustment in steps of 0.2-0.3 ° C.

- Set individual time schedules for each day of the week.

- Quick selection of the standard program and the creation of algorithms based on personal preferences.

- The use of safety relays, in which the formation of sparks during switching is avoided.

- Maintainability in a wide range of temperature and humidity.

Some important details are shown in the pictures.

How to purchase a temperature sensor for a heating boiler: market overview

| Drawing | Brand / Model | Adjustment range, ° C | Minimum actuation step, ° C | price, rub. | Comments |

| Salus / Controls RT100 | 5-30 | 0,5 | 880-980 | The simplest model, without a screen. Suitable for the adjustment of warm floors. |

| Thermoval / RTE-E-3502 | 5-30 | 0,5 | 1050-1200 | Protection against external influences according to IP30. |

| Thermix / РТ001Н16М | 10-40 | - | 1900-2050 | Mechanical control. |

| Salus / Controls T105 | 7-30 | 0,4 | 2050-2200 | Programmable controller. Monochrome display with backlight. |

| Poer / PTC10 | 7-32 | 0,5 | 2100-2250 | The ability to connect to the Internet using an additional set of equipment. Wireless connection of the receiver and thermostat. More than 20 programs. |

| Salus Controls 091FL | 5-30 | 0,5 | 2180-2300 | User programs, frost protection system. |

| Grand Meyer / PST-2 | 5-35 | - | 3400-3600 | Concealed installation, programmable controller. |

| Warmehaus / Touchscreen | 5-35 | - | 7300-7950 | Touchscreen monochrome screen. |

| Salus / Controls iT500 | 5-35 | 1 | 10800-11300 | Remote control, touch screen, Internet connection. |

How to connect the thermostat to the boiler

It is more convenient to work with temperature controllers for heating boilers that support a wireless connection. For an example, the algorithm for installing the Salus / Controls iT500 is shown:

- The controller unit of such a device can be placed in any room at a distance of 30-50 meters from the receiver. It is desirable to prevent undesirable external influences on the thermostat. It is fixed on interior walls, away from, not under direct sunlight. But installation in niches, other places where natural circulation of air streams is difficult is not recommended.

- The distance will be shorter if there are thick reinforced concrete walls on the corresponding line, other obstacles to the propagation of radio waves. The signals are transmitted at a carrier frequency of 868 MHz.

- If several sets are mounted on the object, you can change the encoding. To do this, use a switch type DIP. Suppose a choice of 32 options. The distance between the receiving blocks is more than 90 cm to avoid false alarms.

- The Salus / Controls iT500 is designed in a safe design that allows use near gas equipment.

Previous operations are performed when the power is turned off 220 V.

General conclusion

The use of a wireless thermostat for a gas boiler simplifies the operation of heating equipment. The simplest models are inexpensive. But their installation is associated with the laying of wired communications. Therefore, the total costs can significantly increase in comparison with the preliminary plan. In more complex sets, a radio band is used to transmit control and pilot signals. Installation of such products is not difficult to perform independently. Their high cost is explained by the expanded functionality.

Many owners of private houses arrange an autonomous heating system in the dwelling, which ensures the effective creation of a comfortable atmosphere in the rooms of the dwelling. Any such system has the ability to adjust the temperature level. This is due to the thermostat for the boiler. It is due to him that the owner can change the temperature to create a favorable climate in the home and the opportunity to reduce energy costs while operating the boiler.

The purpose of thermostats and characteristics

At the heart of the work of this device is the principle of switching on and off the heating boiler. Before this, a temperature sensor is installed in the device. This device is easy to control and at the same time demonstrates sufficient reliability on the management of the temperature in the rooms of the house.

At the heart of the work of this device is the principle of switching on and off the heating boiler. Before this, a temperature sensor is installed in the device. This device is easy to control and at the same time demonstrates sufficient reliability on the management of the temperature in the rooms of the house.

The main advantage of using the thermostat in the heating system is the ability to reduce energy costs.

It does not matter whether the unit is running on gas or is powered by electricity. By the parameter, as a functional purpose, all temperature controllers are divided into two types:

- manual;

- programmable.

Which thermostats are better

Hand-held instruments are equipped the on / off button. In addition, the thermostat has a temperature adjustment dial, which rotates manually.

Programmable thermostats have more complex device. However, this does not mean that their use is problematic. Complex designs provide more opportunities that are available to the owner using a heating system with a built-in thermostat.

One of these is the switching on and off of the boiler in automatic mode at certain intervals that are set by the user.

Classification of thermostats

For reliable operation of wired temperature regulators, special attention should be given to the quality installation of conductors.

For reliable operation of wired temperature regulators, special attention should be given to the quality installation of conductors.

This must be done to ensure their uninterrupted connection with the boiler. The signal arriving at the thermostat leads to the start of the feeding process to the heating circuit of the coolant.

By their performance, thermostats are divided into the following types: wireless and wired.

In wireless devices, the process control is carried out by using a radio signal, which goes to the temperature sensor.

Usually in the thermoregulator for boilers there are two units. Installation of one of them performs in the immediate vicinity of the boiler, it is connected by its terminals.

Installation of another is carried out in a heated room. On the dedicated radio channel, these two units communicate with each other. The main difference between the main block and the executive is the availability of LCD and keyboard.

Automation classification

By the same criterion as the automation level, thermostats are divided into the following groups:

- Analog.

- Digital.

The characteristic features of analog devices are that they are manually controlled, for which purpose mechanical regulator, which is directly related to the rheostat.

Through signals of the chip the digital device is controlled. The use of equipment of this type allows the use of a large number of temperature regimes in the operation of the heating system.

Classification by type of sensor

Depending on the sensor installed in the thermostat, these models are divided into mechanical and electronic sensors.

Instruments that have mechanical sensors in their equipment are on the market capillary thermostats. They consider the temperature by changing the total volume of the heated liquid in the sealed flask. In the heat exchanger located in the heating device, such a sensor is immersed.

The main positive feature is the accuracy and durability. As for the shortcomings, the main thing is incompatibility with programmable controllers.

If an electronic sensor is installed in the thermostat, when the controller is operating, it will read the signals from the thermistor. The thermistor itself measures resistance under the influence of temperature.

Device Advantages

It should be noted that if a programmable thermostat is installed in the heating system of a private house, designed for a gas-fired boiler, then it has the following advantages over simple devices:

When choosing any device for a boiler, it is first necessary to start from the requirements that are imposed on its functionality.

If for you are not important serious functionality of the device, then you can install a simple device in the heating system. In most cases, owners acquire programmable thermostat due to its good functionality.

How does the thermostat work?

The principle of the device from different manufacturers does not have any significant differences. They can have even the same appearance. The difference is only in minor details. In terms of functionality, they practically do not differ from each other.

The principle of the device from different manufacturers does not have any significant differences. They can have even the same appearance. The difference is only in minor details. In terms of functionality, they practically do not differ from each other.

When the device is operating coolant heating control and ambient air, which uses a sensor, which can be built-in or external. The controller sends a signal to turn off and turn on the automatic unit installed on the heating boiler.

A trip signal is received if the temperature of the coolant or the ambient air rises above the set value. When it falls below a given level, then the switch-on signal is given heating equipment.

Features of installation work

If the owner decided to install a thermostat in the heating system, then this work can be done by one's own hands. It is advisable to install the device in the coldest part of the house or where most people live in the house.

Typically, the installation of this device is carried out in a place convenient for use and which provides free access to it.

Before installing the thermostat for the boiler, you must select the location to which constant air supply. This is necessary to ensure its proper operation.