A holiday plot and a country house are a big volume of problems that arise every day. They have to be solved, not leaving for later, because the unsolved problem is doubling every day. Therefore, when the owner of a suburban area is faced with the issue of the electrical connection of some device or service facility located next to the main house, this is another problem that can be solved simply by knowing the requirements and rules for conducting electrical wiring. So, let's consider in this article the question of how the cable is laid in the ground in the suburban area.

Pay attention, it is in the ground, and not by air. Although, as experts say, both options are usually used by summer residents, when this or that task is being solved.

Let's begin our analysis of the topic by indicating some concepts and terms, where the main concept is a branch. That is, any wiring of the cable from the house, through which will be connected, for example, a garage, a sauna, a summer gazebo, street lighting, are called offshoots. And it does not matter, these are air lines or underground ones.

We do everything by law

Smart people try to conduct their business on one very important principle, which says - you have to do everything so that you have everything, but for this you would not have anything. And since the supply of electricity is one organization, it turns out that you have a deal with a monopolist. And, means, to change conditions of granting of its services in any way it is impossible. That is, in this case you play on his field.

Therefore, you can not change legislative acts. And they say that any branch from the original transmission line is the property of the power grid. Even if you have made a wire from your own home to your own garage, it is not your property. Therefore, the monopolist, or rather, his representative in the form of GorSvet or Ray Light should serve any branch and monitor its quality and condition. And, of course, he is fully responsible for all this.

Therefore, advice. If you want your new branches to be accepted by the representative electrical networks immediately, coordinate them in advance. You can invite a representative to your site to do this, you can draw a plan (diagram) of the posting and take it to the office of the company. The ideal option is to completely transfer the project to an electricity supply organization.

- Firstly, the project will be done according to the SNiP.

- Secondly, the company itself will conduct the installation.

- Thirdly, the connection and the act will also be conducted by the company.

- Fourthly, they will serve this branch.

You have to pay for all this. As practice shows, this is the most optimal option to avoid problems and stress.

Do it yourself

If you think that you will cope with all your work, then you will have to plan the ongoing process. So, our task is to install the cable in the suburban area under the ground with our own hands. Let's start with the fact that the transition of the cable to the ground can be made from overhead line or from a common switchboard, which is most often mounted on a wall.

Most often for underground wiring is used armored cable. For example, WBBH. This is a copper cable, which has a different cross-sectional area. By the way, before you buy wires, you need to accurately calculate what current load they will withstand. If the budget of the electrical work is limited, instead of an armored cable, you can use the usual, for example, VVGng. It is simply cheaper in view of the lack of an armored braid.

Underground laying conditions

- The vertical section from the shield to the surface of the ground can be completed with a metal pipe or corner.

- In the horizontal sections, plastic pipes are used. And in this case, the length of the branch does not matter, because the pipes can be connected to each other in any length.

Attention! The height of the closed vertical section should not be less than 1.8 meters.

- As for laying the cable under the roads, in this case either metal pipes or asbestos pipes are used.

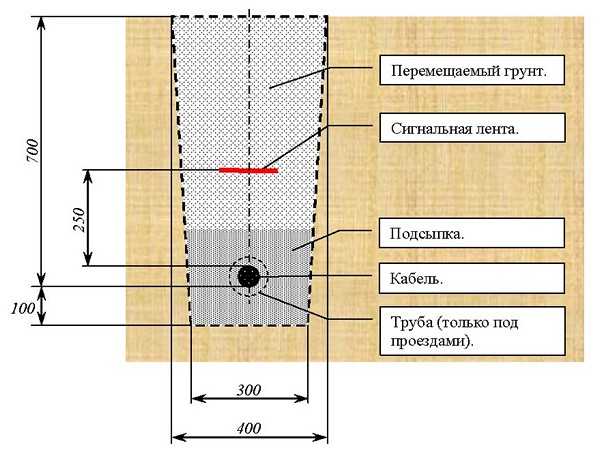

- Excavated trenches should be at least 70 cm deep. At the same time, the bottom is necessarily covered with a sand layer of 10 cm thickness. If the cable for laying in the land in the dacha is laid outside the pipe, then after installation it is also covered with sand. In this case, the thickness of the second layer above the cable must be at least 10 cm.

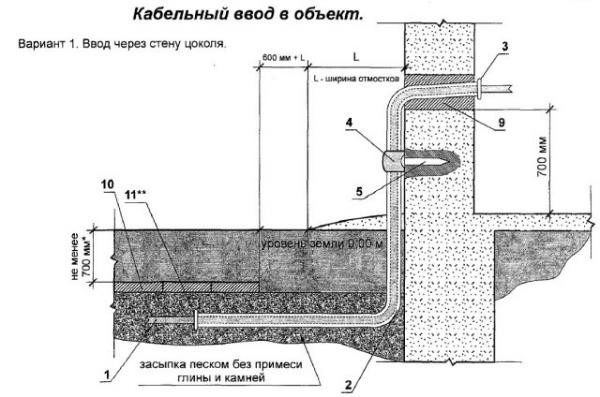

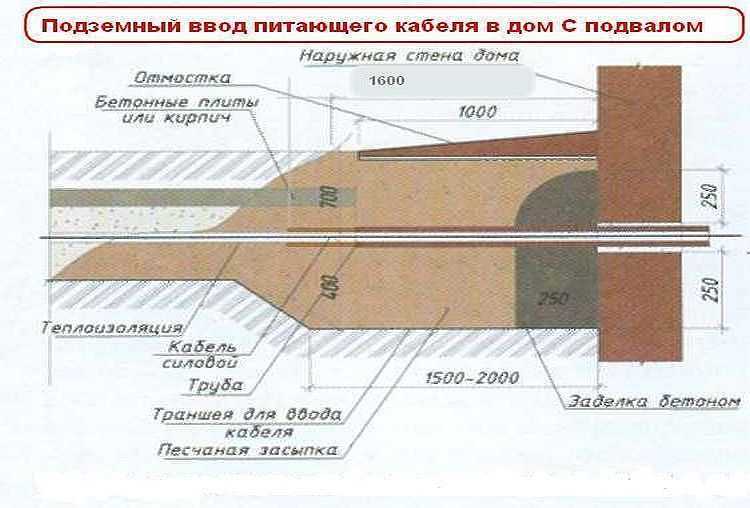

- The entrance to the house must be carried out through a special metal clutch, if the wiring passes through the wall. If through the foundation, then the metal pipe is laid. This element is necessary only so that shrinkage of the house and foundation does not lead to damage to the electrical wiring.

Trenchless gasket

This type of cable installation is also used to build a branch in the suburban area. This way you have to overcome obstacles, or if the house is built on rocky ground.

There are in this category of branches one way, which today is used by many summer residents. Call it a puncture. Of course, this is not the puncture that is done by special equipment. This process is carried out manually with the help of a pipe and a sledgehammer, so the one who will make a puncture on your site must have great strength and endurance. How is the puncture done manually?

- The first thing from two sides of the obstacle is digging holes, which will be located on the same axis of the puncture.

- The teeth are cut out at the end of the pipe, that is, the end will be in the form of a crown. This can be done by a Bulgarian. In this case, the diameter of the pipe is selected for the diameter of the cable, but it should not be less than 20 mm.

- The pipe is installed in a pit on one side of the obstacle by a crown forward. Then on the back of it you have to beat a sledgehammer.

- Every half a meter the pipe is removed and the internal cavity is washed under the pressure of water. If the soil is sandy, then you can do without water, tapping the walls of the pipe with a hammer.

- If the length of a piece of pipe is not enough to penetrate the ground to the second pit, another piece is welded to it, which is fastened additionally by the armature.

- As soon as the crown teeth appeared on the opposite side, the process can be stopped. The crown is cut off, and a part of the pipe protruding from the opposite side is also cut off. The tube itself remains at the puncture site, it will perform protective functions.

When electrifying a private house or giving, it is necessary to decide whether the route will pass through the air or in the ground. The laying of the cable in the ground requires more work, but it provides greater safety: it is more difficult to draw wires out from under the ground than to cut off the cable. Therefore, despite the high cost, this method is more often chosen.

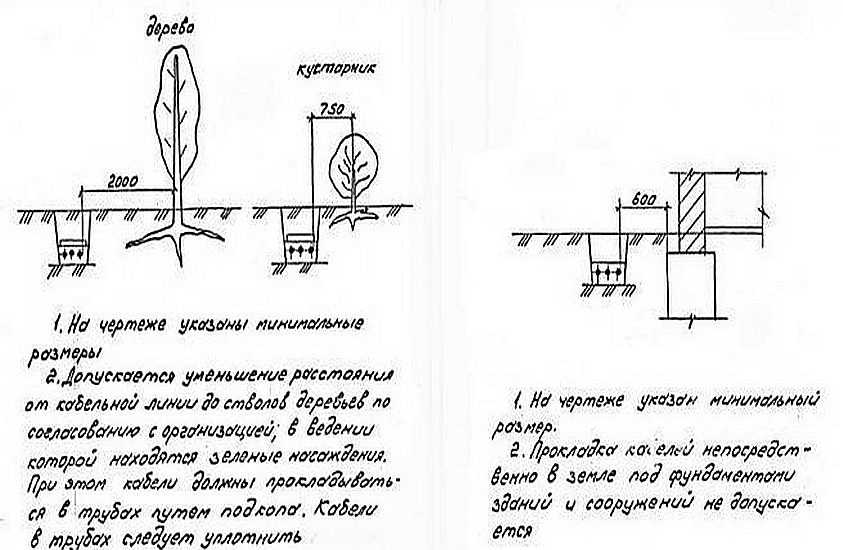

The route of the underground cable laying from the post to the house will be traced in the project and all you have to do is follow all the instructions. But when the electricity is routed around the site, the route has to be developed by yourself. The most economical option is a straight line from one point to another. But the real route is almost impossible. Most often this is a broken line, as many obstacles must be avoided.

How to build a route

When planning a route, you must adhere to the following rules:

Drawing a plan

After you roughly imagine a route, transfer it to a sheet of paper. This plan should also include basic facilities, water supply, sewerage, etc. After you dig out the trench and lay the cable (before starting the backfill), measure the distance to all "long-term" objects and transfer them to the plan.

Professionals call this process a "snap to the terrain." This plan with distances can later be very useful - with re-planning the plot, planning new buildings, etc. Also it will be if there is a need to repair the transmission line. According to the plan, you will restore the place of the route.

Cable protection from above

When laying a cable in the ground, there is always a high probability that it may be damaged when carrying out any earth work. Because the PUE provides for protection over the route. For high-power cables (1 kW and above), protection with concrete slabs or solid bricks is required. For low-power lines, which usually feed our homes, it is allowed to lay the cable in the ground with signal plastic tapes. This method of protection is permitted if there are no more than two conductors in the trench.

Lay signal tapes along the cables at a distance of 250 mm from their outer cover. If the power line is one - the tape is located above it, if there are two or more, put two or more tapes. Their edges should protrude beyond the cable by at least 50 mm, and adjacent ribbons should be placed with an overlap of 50 mm.

Underground cable laying technology

The laying of a cable in the ground means digging a trench all along the route. The recommended depth is 70-80 cm. If for some reason you can not dig into such a depth, you can reduce it, but lay the line in pipes or a protective shell. This can be corrugated hose or special pipes, in which the outer shell is made of harder polypropylene, and the inner part is made of softer polyethylene.

You can still use asbestos-cement or plumbing plastic of suitable diameters. Why not sewer? Their walls are thinner and they can not protect themselves from a serious load. Do not recommend the use of metal pipes, but already because of their excessive rigidity: with soil movements, their hard edge can wipe (and often grind) the shell. Therefore, if you lay the cable in metal pipes, they will have to be welded along the entire track and think about how to make the edges not so tight.

If pipes are used on the cable route, their edges should be sealed. So in them the earth will not be filled, water will not fill. The easiest way is to add a little mounting foam to the edge, but you can also use cement-cement mortar soaked in cement milk rags. To whom that is more convenient. Just do not forget that the cable inside should not be taut. There should be a slight slack.

In addition to depth, you need to decide on the width of the trench. For one cable, it is recommended to be 25-30 cm wide. When laying two or more, there must be at least 100 mm between them. In addition, from the extreme cables to the wall, the distance is not less than 15 cm. In accordance with these recommendations, the width of the trench is determined.

List and order of work

Cable laying in the ground begins with excavation work. According to the plot and selected parameters, we dig a trench, simultaneously removing all hard and sharp objects from the walls. Walls are desirable to do with a slight bias - so they will less crumble and work so conveniently. When the trench is ready the order of work is as follows:

On this the cable laying in the ground is over. But there are still features and nuances.

Before laying the cable in the ground and after backfilling it is very desirable to check the insulation resistance. For this case, use a megger that supplies high voltage, checking the quality and condition of the insulation.

After checking, do not forget to remove the residual voltage by shorting the wires to the ground. This operation should be carried out with great care, since with good insulation quality and a long track, the voltage can be very considerable. The defeat has serious consequences - up to a lethal outcome. Therefore, when working with an ohmmeter and when removing the residual voltage, do not forget about dielectric gloves, glasses.

Since an ohmmeter in a household is rare, cables in vinyl insulation can be checked using a conventional tester or voltmeter. They do not measure the insulation resistance, but the presence of a breakdown or a short one between the conductors will show. We call all the conductors with each other, as well as everyone with the earth, screen or armor. If there are any problems, do not use this piece.

When laying and filling with sand, make sure that insulation is not damaged. After installation, also check the insulation, or ring the wires. What happens, if you apply to a conductor with a broken insulation, you probably know.

Bury in the ground better one piece of cable without connections. If this is not possible, make a connection of two pieces above the ground in a special junction box for the street. The box can be fixed on a column which is dug in the place where the cables exit to the surface. Doing homemade clutches is unreasonable, since they have a low quality and they, usually, are sources of problems.

If several lines are laid in a trench, and they must pass in a protective shell, then each shell must have its own.

How to enter the house

Entry into the house of a cable laid under the ground can be done in several ways, but it's not permissible to simply conduct it through the foundation. There are other methods:

Cable laying in the ground requires attention. It is very important not to damage the insulation during the work, otherwise you will have to re-do everything.

Which cable can I use?

For laying the cable in the ground, you need to use products with a high degree of protection against moisture, in a rigid shell. These conditions are satisfied by the vinyl and polyethylene shell. These cables are usually used: VVB (armored), VVBbG (armor + waterproofing), VBbShv (armor + polyethylene hose). But they are expensive, although they serve for a long time. It is advisable to use them to put electricity from the post to the house.

When choosing the type of armor, you must pay attention to the acidity of the soil, the number of large stones, construction debris. For neutral soils with small impregnations of stones, steel armor fits. It will also go for clay and loam. Acidic or alkaline soils require lead or aluminum armor. The same cables are better used on soils with normal acidity but with a lot of stones.

You can make wiring on the site cheaper conductors. Normally, NYM and CIP feel. They can work up to 5 years. VVG use for underground laying is definitely not worth it. It lasts a maximum of a couple of years, which, given the volume of land works, does not please.

In general, it is wiser to build more expensive cables, but with a better protective shell. Let it cost more at the stage of the device, but there will be no problems and will not have to think about replacing a new one in a couple of years.

Liked the video? Subscribe to our channel!

One of the most popular species cable products is a cable for laying in the ground. It is used to provide power supply for buildings and structures, decorative, street and landscape lighting, power supply for tents and tents, as well as in many other situations.

Regardless of the purpose of the work, the laying of the cable under the ground must be carried out in accordance with the SAE and the PTEEP. Even before the beginning of work, it is necessary to choose the optimal brand of cable. Most often the best option is an armored cable for laying in the ground, which is well protected from mechanical damage. It is also possible to install other cable brands without armor, but then they must be placed in asbestos-cement or special PVC or PE pipes.

Trench preparation

Before starting the installation work, you need to check if there are any crossings of the cable route with any other engineering networks. This information can be obtained from the results of studying the geodetect of the cable path being laid.

If there are no engineering systems in the way of laying the cable route, you can start preparing the trench. Its depth depends on the terrain in which it will pass. If the cable laying in the ground is planned under the road, the depth of the trench must be at least 1.25 meters. In doing so, digging a trench carefully, because in the ground there may be engineering systems that are improperly applied to the geodetic scheme - such incidents are very common. If you plan to lay the cable in the ground under the lawn, it is enough to dig a trench from 0.9 meters deep.

In the finished trench you need to pour a sand pillow that has up to 15 cm of thickness - this is required by the rules of laying the cable in the ground for additional marking of lines and their greater protection from mechanical damage. The sand is heavily wetted with water and ground.

Cabling

As a rule, cable laying under the ground implies the use of a cable with armor, which will provide protection against mechanical impact. If nevertheless it is intended to use non-armored cables, then it is necessary to select brands that have the necessary resistance to thermal and mechanical influences in the course of maintenance operations. Due to increased requirements, it is most often used just an armored cable for laying in the ground.

When laying the cable for a voltage of up to 1 kV, it must be protected with a brick laid across the cable route in places with an increased likelihood of mechanical damage. Also, the cable can be protected with reinforced concrete slabs. After completion of each stage of electrical work in the trenches, to verify the integrity and integrity of the cable sheath, it is necessary to perform control electrical measurements - and, first and foremost, measure insulation resistance. The resistance value is indicated in the GOST or TU for the cable, and by its deviation from the standard it is possible to determine the presence of external damages.

The types of cables used for laying in the ground

In many respects the characteristics and durability of the cable depend on its isolation. Modern cable for laying in the ground can have the following types of insulation:

- paper impregnated insulation;

- plastic insulation (polyethylene or PVC).

Paper impregnated insulation of cores has excellent electrical characteristics, long service life, rather high permissible temperature at low cost. The disadvantage of paper insulation can be called hygroscopicity, which requires complete tightness of the cable sheath. Also, the composition impregnating the paper, with a significant difference in the levels of the gasket along the length, can gradually drain to the lower end, which somewhat reduces the insulation strength, worsening the cooling conditions and shortening the life of the cable. Information on the allowable difference in the levels of laying of such cables can be found in the reference literature and the TU of the cable.

Plastic insulation for power cables is made of polyethylene or PVC (polyvinyl chloride). Such cables are laid in tunnels, fire-dangerous channels, in an aggressive environment, provided there are no mechanical influences. For installation in trenches, a plastic power cable is most often used for laying in the ground, reinforced with tape armor, such as, for example, or PvBhShv.

For laying in a soil containing substances destructively affecting the cable sheath (solonchaks, bulk building material and slag, bogs, etc.), as well as in areas of increased exposure to electrocorrosion, cables are used in the lead shell. Also under these conditions will be an effective power cable for laying in the ground with an aluminum sheath, for example. Cables with wire armor, such as (steel wire) or PvKaShp (aluminum wire), can be used in places with an increased risk of mechanical damage.

Common brands of cables for laying in the ground

In soils with low corrosive activity, a cable is used for laying in the ground the following grades: