Dielectric mats are used as an additional measure of protection when working with electrical installations under high voltage. The material from which the product is made must meet the established requirements. Depending on the purpose, the size of the litter is selected, and the storage time is also taken into account when purchasing, which is limited to three years.

Metal pairs supported by external energy are supported only until the current passes through the natural zero. At this stage, a rapid decrease in load density and rapid condensation of metal vapor leads to a very rapid recovery of dielectric properties. In this way, the vacuum interrupter restores the insulating capacity and ability to withstand the transient recovered voltage and finally extinguishes the arc. Since high strength electricity can be achieved in a vacuum even at minimal distances, circuit breaking is also guaranteed when contact separation occurs a few milliseconds before the neutral current passes through. 4.

Purpose of products

Dielectric mats are an additional means of protection. High potential can penetrate personal equipment: gloves, boots, current measuring instruments used. In areas of ungrounded metal supports or when high humidity gender, such measures are simply necessary.

In addition, the vacuum prevents oxidation and contamination. Therefore, the switch requires minimal maintenance. These characteristics allow switching on and off independently of the operator. This simplicity translates into greater reliability. Design The drive and poles are mounted on a metal frame, which also supports the fixed-mount switch. Compact design ensures durability and mechanical reliability. In addition to disconnecting contacts and hoses with auxiliary circuits, the retractable version is equipped with a chassis for insertion and ejection into a switchboard or enclosure with the door closed.

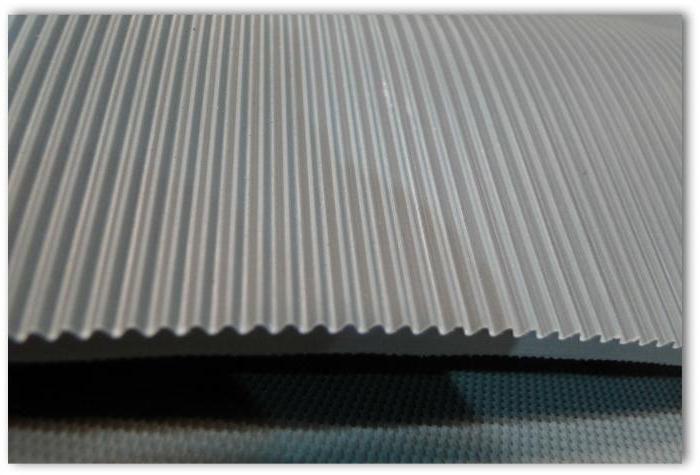

At voltages up to and above 1000 V, it is mandatory to use dielectric mats. When working with any increased voltage, a corrugated surface made of a special material is placed under the personnel’s feet. It is resistant not only to potential, but also to oils and mechanical wear.

Requirements for protective products

Dielectric mats meet the requirements regulatory documents: GOST 4997-75. The material of the product is able to withstand numerous bending cycles. The shelf life in the warehouse is 3 years, after which the manufacturer recommends changing the protective equipment. This is due to the properties of rubber to change its composition under the influence of air: it hardens, becomes brittle, and loses its ability to insulate surfaces.

Vacuum shutdown technology Vacuum contacts are protected from oxidation and contamination. Vacuum breaker built into polymer poles. The shield is protected from damage, dust and moisture. A channel arc in a vacuum is characterized by decomposition over the contact surface and a uniform distribution of thermal stresses on the contact surface. At the rated current of the vacuum interrupter, the arc is always of the diffuse type. The erosion contact is negligible and the number of power outages is very high. As the value of the operated current increases, the electric arc tends to transform due to the Hall effect from a diffuser to a conventional type.

The surface of the mat is corrugated and anti-slip, the depth of the grooves is about 1-3 mm. The material can withstand voltages up to 20 kV with a frequency of 50 Hz. The leakage current is measured, which does not exceed 16 Ohm A/sq. m. Structure appearance should be uniform, dark tones predominate in it.

Types of protective equipment

Products are divided into the following types:

The arc begins to taper at the anode and tends to become sharper as the current increases. Near the affected area there is an increase in temperature followed by thermal contact voltage. To prevent overheating and erosion of the contacts, the arc rotates. As the arc rotates, it is like a moving current with current flowing through it. The special geometry of the helical contacts creates a radial magnetic field in all areas of the arc column centered on the contact circuits. The electromagnetic force is generated automatically and acts tangentially, which causes fast rotation arcs around the contact axis.

- An ordinary dielectric mat, the price is low, the service life is limited.

- Oil and petrol resistant used in aggressive environments. Often placed on stands.

Depending on the conditions of use, the dielectric mat has a fixed size. The price depends on the dimensions. Products are divided according to standard values:

This means that the arc is forced to rotate and cover a wider surface area of the solid arc of the contract. In addition to minimizing contact thermal stress, this results in negligible contact erosion and, in addition, allows very high currents to be interrupted short circuit. The rapid limitation of current flow and rapid condensation of metal vapor simultaneously with zero current means that maximum dielectric strength can be restored between quench contacts within milliseconds.

They have been subjected to the tests listed below to ensure the safety and reliability of the device with every installation. Current, mains voltage Voltage Short circuit current Break voltage Short circuit release Contact separation Time Voltage recovery Transient regenerative voltage Current and voltage during single-phase vacuum interruption. Arrangement of the radial magnetic field of contacts with a rotating vacuum arc. Piece tests: Dielectric strength test of main circuits and auxiliary circuits alternating voltage, main circuit resistance measurement, mechanical and electrical functional tests.

- Length 500-1000 mm. Can be more than 1000 mm and up to 8 m. Cost - from 100 to 500 rubles.

- Width - 500-1200 mm.

- Thickness - 6±1 mm.

![]()

Specialized dielectric mats are sold at prices above 500 rubles. Stands, depending on the design, can cost several thousand rubles. Unique products made to order (according to the customer’s drawing) have negotiable payment and production time.

Locking devices to prevent incorrect operations and to check the installation, guaranteeing maximum operator safety. Key locking and padlocks allow on and off and/or insertion and ejection. The traction device, when the door is closed, allows the switch to move or turn off in switchboard only when the door is closed.

The insert lock prevents switches from being activated with different rated currents and insert when the switch is on. 7. The drive has a standard set of accessories and spare parts that can be easily specified and ordered. Accessories can be conveniently installed from the front circuit breaker. Electrical connection carried out using connectors. Use, maintenance and operation of the device are simple and require limited use of the device. Drive The mechanical drive is a simple, user-friendly concept and can be customized to suit customer needs with extensive accessories that can be installed quickly and easily.

In humid environments, it is recommended to use an insulated stand. It is a high-rigidity dielectric surface placed on legs made of a similar material. The height of the products starts from 70 mm. The flooring is laid out from wooden blocks with a gap of more than 30 mm. For the legs, special insulators of the CH-6 type are used. Additional protection A rubber mat placed on the surface of the stand can serve as a substitute.

The drive is a stator type, has a standard anti-interference device and is equipped with a suitable locking device to prevent unauthorized access. Each processing sequence can only be executed if all conditions are met to ensure it executes correctly. To facilitate installation or replacement of accessories, suitable stable hinges are provided at appropriate locations. Very reliable drive due to the very small number of components produced using mass production systems.

Checking protective equipment

The dielectric and insulating support are subject to periodic diagnostics for breakdown and integrity of materials. Before use, an external inspection of the mats is carried out; checking for cracks in the material is carried out during bending of the plastic structure. It is recommended to inspect the stands for the presence of chips on the legs and bedding.

Very limited and simple maintenance. Lever for manual spring clutch Terminal block for auxiliary circuits 14. This prevents the circuit breaker from being switched into the frame when the auxiliary circuits are disconnected 19. This prevents the circuit breaker from being switched into the frame when the auxiliary circuits are disconnected 23.

The trigger can be used for both direct current, and for alternating current and is suitable for instant use. In this case, the minimum pulse duration must be 100 ms. It has all the electrical and operating characteristics of a shutter release. 3 Trip Solenoid The trip solenoid is a special degaussing trigger located in the drive. The shutdown solenoid is not an alternative to a second release switch. 4 Trigger Gate Allows remote activation.

If defects are found, mats, flooring and other protective equipment must be replaced. If the stands do not move, then diagnostics are carried out at least once every 3 years. If the defect can be eliminated, then the dielectric must be checked for breakdown in accordance with the standards.

To prevent premature wear of rubber coatings, it is recommended to follow the following rules for using products:

This trigger is suitable for instant and continuous use. For instantaneous use, the minimum pulse width should be 100 ms. The constant power trigger is electrically disconnected from unwanted re-switching.

It has all the electrical and operating characteristics of a shutter release. 24. It can be used for remote shutdown, locked in the on position, or to control voltage in auxiliary circuits. The switch can only be turned on using a powered trigger. It allows you to set a trigger with a set and adjustable time.

- Mats are stored at a temperature of 20-25 degrees.

- Before using coatings that were brought in from the cold, you need to let them warm up in a warm room for about a day.

- Oily surfaces are immediately cleaned without using alcohol solutions to prevent the rubber from becoming hard.

- Personnel should not use wet surfaces during work.

- In cold rooms, a specialized dielectric mat, gloves, and stands are used. There are products that can withstand temperatures from -50 to +80 degrees.

Additional protections

When working in high-voltage cabinets with an electric winch, it is necessary to use insulating devices:

Using this minimum release is recommended to prevent tripping during a momentary power outage or voltage drop in the trigger supply line. If it is not connected to a power source, the switch is turned on. The electronic delay device must be combined with an undervoltage cut-off with the same voltage as the delay device. Three switch disconnectors and five switch contacts are available with 10 auxiliary contacts as standard and maximum number of electrical applications.

- gloves are used not only when taking measurements; welders wear them to insulate them from the ground;

- boots, rubber boots, galoshes;

- for measuring electrical parameters;

- a protective mask must be worn to protect the eyes;

- a plastic helmet is a dielectric;

- specialized electric arc kits;

- When carrying out PPR, current-carrying parts located in the work area are covered with rubber dielectrics.

Personnel servicing high-voltage installations are issued specialized heat-resistant suits. To work at height, ladders and stepladders with dielectric inserts are used.

These contacts are either complementary to the position contacts or an alternative to the position contacts located in the switchgear. It also performs a positioning function. 11 Motor control Performs automatic charging of the circuit breaker drive springs. When the switch is turned on, the gear motor immediately recharges the springs. In the event of a power failure or Maintenance box springs can be laid by hand.

The contact is available in one of the following two configurations: Contact Off: The spring signal is not installed. Contact on: Signal is spring loaded. Locking and interlocking Various mechanical and electromechanical interlocking and protective devices. 13 Make sure that the switch and on-off button allows you to use the on and off buttons only with a special tool. 14 Locking the shutter and lock buttons This device allows you to lock the shutter and switch buttons using up to three 4mm padlocks. 15 Locking with a key in the off position Locking is carried out using a special rotary lock.

font size

ORDER of the Ministry of Emergency Situations of the Russian Federation dated December 31, 2002 630 ON THE APPROVAL AND ENTRY INTO EFFECT OF LABOR SAFETY RULES IN DIVISIONS OF THE STATE... Relevant in 2017

Electrical protective equipment

337. Electrical protective equipment used in State Fire Service units includes:

dielectric rubber gloves;

rubber dielectric galoshes (overshoes);

The non-interruption check is performed in a 20 s cycle between tests. Contact us for approved boat logs. Height. The strength of air insulation is reduced by increasing height, so this must be taken into account when externally insulating the device.

If both switches and some shutdown controls were active, a sequence of shutdown and switchover operations would follow. The over-pump protection device prevents this situation and ensures that after each individual switching on and off it does not trip after switching off. To re-enable, the enable control must be released and then restarted. Production complies with these standards in order to reduce energy consumption, as well as raw materials and waste generation.

dielectric rubber mats measuring at least 50 x 50 cm with a corrugated surface;

scissors for cutting electrical wires with insulated handles (requirements for the specified electrical protective equipment are determined by GOST);

portable grounding conductors made of flexible copper conductors of arbitrary length, with a cross-section of at least 12 mm2 for fire engines, which have a main protection system - protective grounding.

This is achieved thanks to all the measures introduced at the high-voltage plant. Impact assessment on environment over the product life cycle, obtained by minimizing energy consumption and total raw material consumption, is specified at the design stage through targeted selection of materials, technologies and packaging. This allows for maximum recycling at the end of life.

Therefore, we recommend these recommendations at the beginning of our operating instructions: Install only switchgear or switchgear. Therefore, we recommend this recommendation at the beginning of our assembly, operating instructions.

338. Tests of electrical protective equipment are carried out by special laboratories that have permission from the State Energy Supervision authorities. The test results are documented in a report, which is stored in the State Fire Service department until the next test. On gloves, boots, mats, etc. a stamp is placed indicating the date of the next test.

339. Test timing:

dielectric rubber gloves - once every 6 months;

dielectric rubber galoshes - once every 3 years;

dielectric rubber boots - once every 3 years;

scissors for cutting electrical wires with insulated handles - once a year.

Rejection of rubber dielectric mats during external inspections at least once a year.

340. The suitability of protective insulating means for operation is determined by external inspection and testing. An external inspection is carried out daily upon reporting to combat duty by the personnel of the State Border Guard units to which they are assigned.

341. External signs, determining the unsuitability of funds electrical protection, are:

for scissors - damage to the insulation on the handles and the absence of thrust rings and rubber bushings at the ends of the handles;

for rubber gloves, galoshes (bottoms), rugs - punctures, tears, presence of holes;

for portable grounding - destruction of contact connections, violation mechanical strength copper wires (breakage of more than 10% of copper wires).