In order to evaluate the whole variety of existing types of solid-state light sources, let's try to compare the characteristics of LEDs for various purposes.

The general characteristics that can be used in evaluating the parameters of any light-emitting diodes are the emission spectrum, the light output (luminous intensity or luminous flux), the current-voltage characteristic, the electric power of the LED.

The volt-ampere characteristic of all the diodes is to some extent identical in form, the differences consist only in specific values of currents and voltages, therefore we will not focus on it.

Let's start with the simplest representatives

Standard indicator LEDs in round and oval cases have powers of about 20-50 mW and a different emission spectrum, determined by the type of semiconductor used to make it. A typical representative of such LEDs can serve as a round 5 mm AL307 domestic production.

Its technical parameters are shown in the table below.

| Type of | Emission spectrum | Wavelength, nm | Light intensity, mcd | Rated current, mA | Direct voltage drop, V |

| AL307 B | green | 567 | |||

| AL307 G | |||||

| AL307 N | |||||

| AL307 B | red | 655 | |||

| AL307 K | |||||

| AL307 L | |||||

| AL307 D | yellow | 590 | |||

| AL307 E | |||||

| AL307 F | |||||

| AL307 O | orange | 610 | |||

| AL307 R | |||||

| AL307 M |

Since the LEDs of the indicator type have a narrow angle of illumination, the radiation parameter such as luminous intensity, measured in millikandels [mc], is used for the evaluation. AL307 has three gradations of brightness for each color. The spectrum is represented by four colors.

Light-emitting diodes in “piranha” type housings make it possible to obtain high power due to reduced thermal resistance and heat removal to the board through four leads at once. The piranha body has also gained popularity due to its increased mechanical stability - the piranha LEDs are successfully used for the manufacture of automotive light. Almost all major manufacturers have in their nomenclature a family of LEDs in the case of "piranha".

Such LEDs are usually called ultrabright or superbright. The main technical parameters of the LEDs "piranha" produced by the American company CREE are given in the table.

| Type of | Emission spectrum | Wavelength, nm | Luminous flux, lm | Rated current, mA | Direct voltage drop, V |

| CP41B-R | red | 628 | |||

| CP41B-A | orange | 591 | |||

| CP41B-B | blue | 470 | |||

| CP41B-G | green | 527 |

The light angle can be 40˚, 70˚ or 100˚, depending on the modification, which can be determined by the manufacturer’s data sheet.

The piranha building allows you to divert up to 200 mW of power.

The wavelength, which is listed in the table for each color of the glow is dominant for this type of LED. In fact, the emission spectrum of, for example, a red LED may be in the range of 620 to 637 nm.

"Piranha" may be a white glow. White LEDs are made by applying a yellow phosphor to a blue crystal.

The next group - SMD 5050 - can already be attributed to the category of high-power LEDs. As the name implies, these are surface mounted LEDs with dimensions of 5 × 5 mm.

The name SMD 5050 is conditional, since various manufacturers give their designation to this class of LEDs in accordance with the existing system. Maximum power reaches one watt. At the bottom of the body of such an LED, there is usually a special area for heat, although it may be absent in less powerful versions.

SMD 5050 LEDs are usually white in color, because designed for the manufacture of lamps. They can be mounted both on glass fiber laminate and aluminum PCB. The latter is used for better heat removal at high power.

The white emission spectrum of such LEDs has different color shades. For them, they introduce such a characteristic as “correlated color temperature”, which is measured in kelvins [K].

The angle of illumination is 115˚.

Below are the main characteristics of light-emitting diodes CLN6A, as one of the best types in this class (the full list of possible versions is quite large, so two typical representatives are given).

As can be seen from the table, the emission spectrum affects the amount of luminous flux - this is the rule for all white LEDs.

In order to accurately determine the characteristics of a white LED, it is necessary to know its full designation, since all the different parameters are encrypted in it using the so-called bins. For example, the XPEWHT LED can have a bean in the light flux Q5 (107 lm at a current of 350 mA), or it can be R2 (114 lm) and R3 (122 lm). Error or incomplete marking when ordering can lead to a “shortage” of lumens by 14% (if instead of R3 we get Q5). The same can be said about the emission spectrum. Carefully read the manufacturer's documentation!

LEDs are among the most sought-after electronic components, and in many different areas of production. The most important nuance of their involvement is correct classification. Its methodology may be based on the use of special LED markings. What can they be? What is the industry specificity of their application?

LED Overview

Before studying what, on the basis of what principles LED marking is carried out, consider the basic information about the corresponding type of products. What do they represent?

An LED is a special diode that glows when an electric current passes through it. The main component of this product is a semiconductor substance. What additives it contains determines the color when the LED is illuminated. For example, if aluminum is added to the semiconductor, then the color of the LED to which an electrical current is applied may be red. If indium is added blue. In modern industry, LEDs are available in the widest range of modifications based on the content of impurities.

Considered products (marking of LEDs can reflect this feature) are applied in the widest range of industries: in the manufacture of lamps, televisions, decorative elements, etc. In these areas, LEDs in many cases have no analogues, and if they are, then they are products in many cases there are undeniable advantages.

For example, if we compare the traditional incandescent and LED, then the latter may be preferable, because:

They will have significantly lower power consumption;

They will have a longer service life;

They are able to work at reduced voltage;

They are characterized by environmental friendliness, safety of operation.

LED design

Another aspect that will be useful to examine before considering how LED marking is applied is the design of the corresponding elements. They consist of:

Lenses (most often made of epoxy resin);

Wire contact;

Crystal;

Reflector;

Electrodes;

Anode and cathode.

How do LEDs work?

How do LEDs function? The reflector of the corresponding element includes an LED crystal. The corresponding component sets a specific scattering angle. The light generated by applying a voltage to the LED passes through the layers of the housing, then it hits the lens, and then begins to diffuse.

It can be noted that the LEDs are capable of functioning both in the visible color range and in the infrared. This feature emphasizes the versatility of the products in question. To indicate the color of the corresponding product can be used LED marking. Consider its features in more detail.

What are the features of labeling LEDs in color?

First of all, it should be noted that the unified unified marking of LEDs in color on the world market has not yet been approved. Each manufacturer uses its own approaches to classify the relevant products. If we talk about the Russian market - in our country the classification of LEDs is widespread into 4 types:

Red;

Green;

Orange.

Let us consider it in more detail in the context of labeling relevant products.

Red LEDs on the Russian market: labeling

If a red stripe is used as the marking of the Russian diode, then it will be of type AL112A (G) and will glow red. If the marking is represented by a green stripe, then the LED will be classified as AL112B (D) and will also glow red. In turn, the blue bar indicates a product of the type AL112V. However, it also has a red color. The same color will be in the following LEDs marked with a red dot: AL112E (K), AL301A, AL310A, AL316A, as well as PIKM02A-1K.

However, there are red LEDs:

AL112ZH (L) and AL307G with a green dot;

AL112I (M), AL310B, and AL316B with a blue dot;

AL307A, AL307V, AL336K, and also KIPD02A-1K with a black dot;

KIPD02B-1K with two black dots;

AL301B, AL336B, and also KIPM02B-1K with two red dots.

There is also a product of the type AL307B without marking - also a red glow. Let us now consider what kind of green LED marking is used in the Russian market.

Green LEDs

So, the following products have green color of a luminescence:

KIPD02V-1L with a black dot;

AL336I with a white dot;

AL336G, and KIPM02G-1L with two green dots;

KIPD02G-1L - with two black dots.

The next product type common to the Russian market is yellow. Consider what is the marking of LEDs, decoding it in relation to products of the appropriate type.

Yellow LEDs

LEDs that have a yellow glow include:

AL336D - with one yellow dot, AL336E - with two, AL336ZH - with three;

AL307D, KIPD02E-1ZH - with one black dot, AL307E and KIPD02E-1ZH - with two;

KIP02D-1Zh - with three green dots.

The next common type of product is orange. Let us examine what is the marking of LEDs (LED) of the appropriate type.

Orange LEDs

Products that have an orange glow include:

LED AL307I - marked with a white dot;

LED AL307L - with two white dots.

There are many ways to apply these products. Accordingly, the marking of LEDs (LED) may be classified for other reasons. So, among the most common applications of these products is the manufacture of light strips. Consider how LED marking is applied when considering the design of this type of product.

Features labeling LED strips

It is worth noting that the production of LED strips refers to the types of business, which are characterized by the same unified approach of brand manufacturers to the labeling of their products. So, for classification purposes, a unified code consisting of 8 elements is applied. It is presented in the following structure.

In the first element of the corresponding code, the name of the main component of the tape - an LED, an LED, is encrypted.

The second element of the code reflects the color of the corresponding product:

R - red - from English Red;

G - green - from Green;

B - blue;

CW - white;

The RGB code reflects the fact that the LED is multi-color.

In the third element of the considered code, by means of which the LED is encrypted - marking of the findings. For example, they can be classified as SMD. That is, the code will show that the chip is intended for installation directly on the PCB, as part of surface mounting. In turn, in the unified code can also be applied marking LED type DIP, which will show that the products are intended to be installed not on the surface of something, but in the holes.

In the 4th element of the unified LED code, the size of the case in millimeters is reflected. In the 5th - the number of relevant products on 1 meter of tape on which they are installed.

In the 6th - the class of protection of the LED from the effects of various external factors. Here, for example, an IP code can be applied, which reflects the fact that the protection class is specified in accordance with the industry standard IEC-952 electronic device protection standard.

The 7th element reflects the degree of protection of the LED. Here may be present codes:

0, indicating that the LEDs are not protected against external factors;

1, indicating that the product is protected from the penetration of objects whose diameter is 50 mm or more;

2, reflecting that the LED is protected from exposure to objects with a diameter of 12-80 mm;

3, showing protection against objects with a diameter of 2.5 mm or more;

4, reflecting the security of the LED from objects with a diameter of 1 mm;

5, showing that the product is protected from dust penetration in the amount that can lead to a violation of the functionality of the LED;

6, which indicates that no dust is allowed to enter the product.

In turn, the 8th element of the unified code reflects the degree of protection of the product from liquid penetration. It can be fixed codes:

0, which indicates that the LED is not protected against liquids;

1, reflecting the fact that water droplets that fall vertically cannot enter the product;

2, which indicates that the LED is protected from water droplets, which fall at an angle of 15 degrees;

3, locking protection against drops that fall at an angle of 60 degrees;

4, showing that the LED is protected from water droplets that fall on the product at any angle;

5, which reflects that the product is protected from exposure to a jet of water of ordinary intensity;

6, showing that water cannot flow into the LED by a strong jet;

7, indicating that water will not penetrate into the product even when immersed to a depth of 15 cm;

8, which indicates that the LED will retain its functionality even after prolonged immersion in water.

Deciphering code unified marking LED strip: an example

What would an example of a unified code look like in the structure we considered?

For example, the marking of SMD-LEDs might look like this: LED-R-SMD-5050/60 IP68. It means that:

The LEDs are located on the tape;

Relevant products have a red glow - R;

The tape is made using SMD type LEDs - that is, designed to be installed on the surface;

The LED has a housing size of 50 to 50 square meters. millimeters;

On a tape 60 LEDs are placed, that fact;

In accordance with international standards, the tape can be used in a dusty room, as well as with long-term placement in water - IP68.

Manufacturers of LED strips, therefore, offer their users a convenient and informative classification of products. With its help, effective marking of SMD-LEDs as well as those belonging to the DIP category can be implemented.

Among other common types of products, with the release of which are used the products in question - car headlights and flashlights. It will be useful to study how the marking of headlights for LEDs is carried out, as well as the products installed in various types of flashlights.

Features marking LEDs for headlights

The most important characteristic installed in the headlight of the car - the type of its base. This parameter should be oriented first of all when choosing a car headlight - in terms of its use instead of halogen.

For example, if you select an LED headlight lamp, the following dependencies may be observed between its marking and brightness:

Marking H1 corresponds to the power of 55 W and brightness of 1550 lumens;

H3 - power 55 W and brightness 1450;

H4 - 55 and 1650 for the main beam, 1000 - for the dipped;

H7 - 55 and 1500;

H8 - 35 and 800;

H9 - 65 and 2100;

H11 - 55 and 1350;

HB2 - 60 and 1500 for the main beam, 910 - for the dipped;

HB3 - 60 and 1860;

There are other approaches to the classification, in which can be applied marking of headlights-LEDs. For example, there are separate types of products installed in fog lamps - for example, H8, H10, and H11. Lamps such as W5W, T10, and T4W are installed in the side and side swivel lamps. The specific type of LED, thus, is selected based on the purpose of a particular headlamp.

Marking of LED flashlights

The next product type in which LEDs can be used is flashlights. The classification of related products also has nuances. Depending on the manufacturers policy, the marking of LEDs for flashlights can be both similar to the one that characterizes the classification of LED strips, which we considered above, and is quite unique (although it is certainly in the interests of the manufacturer to make it as close as possible to industry-wide approaches) .

For example, we can consider the classification of LEDs for flashlights of the American company CREE - one of the leaders in the global market for relevant products.

CREE LED flashlights: classification

Products of this brand is divided into 2 main groups - XLamp lights, as well as super-bright. Each of the respective groups is classified into families, which differ in the type of hull and operational parameters. The main classification criterion in this case is the allowed value of the current that passes through the crystal present in the structure of the LED.

It can be noted that the most type XLamp from CREE are products that have a corresponding figure in a value exceeding 350 mA. In turn, the super-bright products operate at a substantially lower operating current — usually not exceeding 50 mA. If we talk specifically about the classification of products CREE, the lights belonging to the group Xlamp, are classified into the following main types: XR, XP, MC.

They are marked, in turn, by the same designations.

It can be noted that all of them are SMD LEDs. Marking that would reflect this fact may not be applied in this case, since there is no product in the corresponding line that does not meet this criterion. Depending on the specific crystal marking of these types of LEDs may be supplemented by the letters C or E.

In turn, the LEDs, classified as super-bright, are divided into groups, which differ mainly in versions. So, the company manufactures products that are labeled as P4 - they have a square cross section and 4 outlets. LEDs adapted for surface mounting, combined by the manufacturer in the categoryPLCC.

Summary

So, we have considered what constitutes the parameters of such products as marking-characteristic LEDs. Their connection, size, operating conditions, security, and many other parameters can be indicated using the appropriate information. The generally accepted classification of LEDs in the global industry is not approved. That, however, may be quite logical based on the fact that these products are used in the widest range of industries.

However, in certain areas in which LEDs are used, their labeling characteristic can be unified. For example, it concerns the production of LED strips. Using a unified code marking, consisting of 8 elements, the user can determine the key parameters of the purchased products.

But in many cases, in order to obtain reliable information about LEDs, it is necessary to use only the classification and labeling developed by a specific brand manufacturer. They can be as similar to those that characterize the approaches of competing corporations, and quite unique.

In many cases, the criterion for the classification of LEDs may be not so much their characteristics as an independent product, as the parameters of the final product in which they are installed. For example, according to such principles, it is possible to classify products used in the design of car headlights - from the point of view of the applicability of LED marking that is most useful to the end user. However, outside the context of the final product, the classification and, as a result, the marking of LEDs can be carried out according to completely different principles.

In recent years, much has been said about energy-saving LED technologies. They talk about the importance of their widespread introduction, about saving electricity costs, about the excellent light characteristics of LEDs and much more. However, no one talks about what kind of LEDs are and how to use them.

The thing is that the world of LEDs is already so big that an unprepared person often has difficulty trying to figure out the features of various LEDs. In order to clarify the situation, we will try to describe in detail all the LEDs on the market and their functional differences from each other.

LEDs can be divided by the following parameters:

by type of application;

on manufacturing technology;

in size and shape;

on color of a luminescence;

lED power;

Now let's look at each parameter separately.

By type of application

There are two main types of LED application: for display needs (“indicator LEDs”) and for lighting needs (“lighting LEDs”).

There are two main types of LED application: for display needs (“indicator LEDs”) and for lighting needs (“lighting LEDs”).

As an example indicator LEDs You can bring LED strip or garland, designed to decorate or create a mood in the interior. Also, the indicator LEDs can be seen in the parking lights of cars, LED traffic lights, indicator lights and other places where there is no need to use powerful, lighting LEDs. In general, the indicator LEDs are low-power LEDs, the purpose of which is to glow at night and be visible.

Lighting, powerful and super power LEDs used in professional equipment for night lighting of various objects: industrial lights and so on. Also lighting LEDs are widely used in, and. Such LEDs can vary in power and glow color depending on the purpose of their use.

By manufacturing technology

According to manufacturing technology, organic light-emitting diodes (OLED), laser light-emitting diodes and standard RGB light-emitting diodes are distinguished.

Organic LED (from the English. Organic Light-Emitting Diode (OLED) - a semiconductor device made of organic compounds that effectively emit light when an electric current passes. The OLED technology finds its main use when creating display devices (displays). It is assumed that the production of such displays will be much cheaper than the production of liquid crystal displays.

The need for preferential parameters demonstrated by organic displays is growing every year. However, currently only indicator OLED LEDs are produced. Their power is very low to use for full night lighting. Perhaps soon humanity will see the flourishing of this technology.

Laser diodes - This is a laser in which the active medium is an electron-hole gas, and the working area is a semiconductor p-n junction, similar to the p-n junction of a conventional LED. Laser diodes are important electronic components. They are widely used as controlled light sources in fiber-optic communication lines. They are also used in various measuring equipment, such as laser rangefinders. Another common use is barcode reading. Lasers with visible radiation, usually red and sometimes green - in laser pointers. Infrared and red lasers are in CD and DVD players. Blue lasers are on the HD DVD and Blue-Ray devices currently entering the market. The possibilities of using semiconductor lasers in fast and inexpensive devices for spectroscopy are investigated.

Until the 1990s, LED manufacturers could produce only red, yellow and green diodes. Thanks to blue LEDs, modern LED lights shine so brightly. However, only a combination of blue, green and red can give a color that is visually perceived by the human eye as pure white, as well as many shades of color gamut. Therefore, before the invention of the blue LED talk about a full-color LED lamp was not necessary.

The first blue LED was created back in 1971 at RCA Laboratories. It was developed by Jacques Pankov (Yakov Isaevich Panchechnikov), the inventor of LEDs on gallium nitride. However, the production technology was prohibitively expensive (gallium nitride film on sapphire substrate).

The revolution in outdoor LED screens and electronic scoreboards took place in 1990 when Japanese inventor Suji Nakamura, who was working for the Japanese corporation Nichia Chemical Industries at the time, invented a cheap blue LED.

By 1993, the company Nichia, the first in the world, was able to begin the industrial production of blue LEDs. By 2002, the company’s share of blue LED production had increased to 60 percent of the total production. Today, except for the company Nichia the largest manufacturers of LEDs are firms CREE (USA) and SAMSUNG (South Korea).

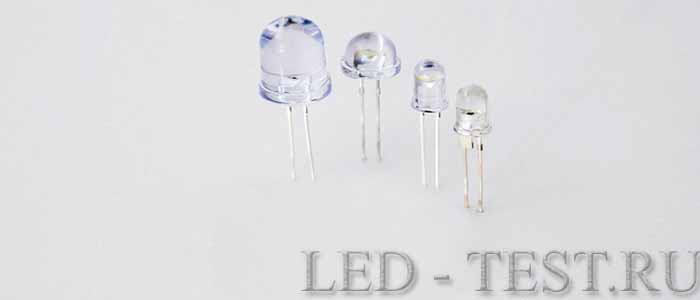

By size and shape

LEDs differ in size and geometry. The most popular are the LEDs in a cylindrical housing, as well as square and rectangular shapes. The dimensions of the LEDs are not regulated, therefore, various manufacturers produce LEDs of various sizes, on average from 2 mm to 10 mm in diameter. Also, LEDs differ in the number of light-emitting crystals. As a rule, there is one crystal in the LED case. However, sometimes, depending on the production technology, manufacturers place several crystals on one substrate. This design is called the LED cluster.

LEDs differ in size and geometry. The most popular are the LEDs in a cylindrical housing, as well as square and rectangular shapes. The dimensions of the LEDs are not regulated, therefore, various manufacturers produce LEDs of various sizes, on average from 2 mm to 10 mm in diameter. Also, LEDs differ in the number of light-emitting crystals. As a rule, there is one crystal in the LED case. However, sometimes, depending on the production technology, manufacturers place several crystals on one substrate. This design is called the LED cluster.

By radiation color

LEDs differ in the color of the radiation. Color depends on the wavelength of the LED. The most common colors are, of course, red, blue, green and white.

LED power

LEDs are bright and powerful. As a rule, the more powerful the LED, the brighter it shines, but also consumes more electricity. However, the power consumption of even a super-bright LED is much less than that of an energy-saving lamp of similar brightness. Thus, when buying a LED lamp should not focus on its power. It is better to pay attention to the ratio of the luminous intensity produced (measured in lumens, Lm) per 1 watt of electricity consumed. A good indicator is 100 lm / W and above. The theoretical limit of the LED is 500 Lm / W, although at the moment only 250 Lm / W have been achieved and only in laboratory conditions.

Conclusion

In general, the choice of the LED, as well as the choice of the LED lamp is not so complicated. However, if after reading this article you still have questions about the LED equipment, we will be happy to help you choose a lamp that suits you!

In order not to get lost among the variety of types and types of LEDs, we need a single standard, according to which all emitting diodes can be divided into groups according to certain parameters. But as it turned out, this standard does not exist, and each LED manufacturer classifies products at its discretion. The reason for this approach is obvious. Optoelectronics is developing rapidly, there are all new models of LEDs made by more advanced technologies.

Unfortunately, to list the main and the minor characteristics first will not work either. Such a division is very subjective. Therefore, it is necessary to proceed to a detailed consideration of the issue so that the reader can visually get acquainted with all the most common types and types of light-emitting diodes.

Color spectrum

Current technology allows you to get a crystal LED with any color of radiation in the visible range. To do this, use chemical compounds of semiconductor materials: indium and gallium with different elements. For the purpose of unification, except for color, another characteristic is indicated on the packaging with the product: radiation wavelength. It helps to identify the shade as accurately as possible. For example, any light-emitting crystal with a wavelength of from 500 to 570 nm can be attributed to a green-emitting diode. In this case, an instance with λ = 500-520 nm will have a sea-green color, and with λ over 550 nm - a lettuce shade. Intermediate colors are obtained by the method of the proximity of three crystals: blue, red and green, followed by control of the power of their glow. These are the so-called RGB LEDs. There are also two-colored types used mainly in the indicator illumination.

A separate paragraph should mention the white types of LEDs. They have a wide spectrum of radiation and are formed, as a rule, on the basis of an ultraviolet LED, coated with phosphor. They have their gradation in shades (warm, neutral, cold), which is expressed in the form of such a parameter as.

Although UV and IR emitting diodes do not work in the visible spectrum, they also deserve a place in the list of types of LEDs for their practical use.

Power

Depending on the destination power consumption can range from units of mW to tens of watts. The first, smallest types of LEDs are unpackaged crystals. They are used to create COB-matrices using the latest technologies. The second type can conditionally be attributed products with a capacity of 60 mW to 1 W (ultra-bright in a transparent case, smd 3528 and their derivatives). The third group will include LEDs with a power dissipation of more than 1 W, requiring the use of an additional cooling system. The most powerful is considered to be the COB-matrix. One such module with a size of 35x35 mm can dissipate up to 160 watts.

The power of light

This characteristic is directly related to such parameters as power, angle of illumination and production technology. The smaller the angle, the greater the brightness at the measurement point. Superbright LEDs with a scattering angle of 110 ° have a light intensity of about 1000 mcd, and from an angle of 15 ° - a light power of 35,000 mcd.

In the American corporation, each generation of high-power white LEDs is entered into a separate group (S5, T6, U3 ...). Thus, the manufacturer tries to isolate each new type of LED having an increased light output at the same power consumption.

It is worth noting that the outdated diffuse LEDs of the AL307 type with luminous intensity of 0.4-6 mcd are no longer in demand and are almost superseded by super-bright analogs with light output thousands of times more.

Voltage drop

The voltage drop of single-chip LEDs is determined by their power and color of radiation and has a fixed frame. For example, a voltage drop of 3.3 to 3.6V may be indicated in the characteristic of a white emitting diode.

The increase of current through the crystal in order to increase the brightness could not continue indefinitely. As a result, the companies have established the release of multichip LEDs, which are designed for voltages of 9, 12, 18, 24, 48, 72 volts. A prominent representative of this family is the COB-matrix of white glow.

One can not forget about the filaments, which are fed with a constant voltage of about 70V. These specific rods are used in filament imitation lamps.

Execution and appointment

If you go into details, this section will become very extensive. After all, each manufacturer produces hundreds of types of LEDs with different geometric dimensions to meet the needs of consumers. And yet there are signs by which you can streamline them.

We list the main types of LEDs:

- Low current:

a) superbright two-lead 3, 5, 10 mm in a round transparent case. Used as indicators in advertising and information modules, traffic lights;

b) smd LEDs are rectangular or square in size up to 3x3.5 mm. Most often used in the construction of running lines and display systems. - Powerful smd:

a) assembled on a single crystal without a lens and used in LED lamps and consumer tapes;

b) collected on several crystals with a common lens and positioned for industrial and decorative lighting. - COB-modules of white luminescence can reach a size of 38x38 mm in a square version and 50x6 mm in the form of rulers. They are in demand in the design of floodlights and street lighting lamps.

- Filament. Made in the form of a rod with a length of about 30 mm with a lot of crystals on the surface. The possibilities of filament lamps are only revealed. While they are used to create a 220V.

- OLED. Thin-film organic LEDs for building displays.

- Radiating diodes in the IR and UV range. They are produced in the case with the findings, and in the smd version. Among consumer goods, they can be seen in the remote controls and lamps for drying nails.

In conclusion, it is worth noting that the above classification is not complete and can still be supplemented by subspecies and groups. the same applies to the ever expanding scope of application. But the general concept that leaders in the production of optoelectronics Nichia, Cree and Philips put forward in this article is described in as much detail as possible.

Read the same

The rapid development of the market for LED lighting "threw" on the market various types and types of LEDs. Most manufacturers divide their chips in a way - "as God puts on the soul." There is no clear classification. But nevertheless, there is a certain “clear line” - a division by species based on common features and characteristics.

For the most part, such a classification is not entirely correct, but justified. There is no exact separation according to the characteristics for one simple reason: if we take the color, then the LEDs can be attributed to one type or type, and for the second (power) such LEDs can hardly be attributed to one form. And since there are a lot of characteristics of LEDs, it is quite problematic to put them together.

Based on this, manufacturers can easily reduce to one class COB and SMD diodes in one group, indicator and lighting in another. In general, there was some confusion on the classification of LEDs based on characteristics.

In order to correct this situation it is worthwhile to accept that any characteristics of the diodes are conditional. Only in this way can they be combined and somehow classified.

Types and types of LED indicator

The following types of diodes should be referred to the indicator types: DIP (DIL), Superflux, Fiber. The first two are quite morally obsolete, but still they can still be seen in many gadgets and devices. There are cases when you can see the use of indicator diodes as lighting. Nonsense today, but it "is the place to be." Let us leave such an application on the conscience of manufacturers and we will consider indicator LEDs in more detail.

The following types of diodes should be referred to the indicator types: DIP (DIL), Superflux, Fiber. The first two are quite morally obsolete, but still they can still be seen in many gadgets and devices. There are cases when you can see the use of indicator diodes as lighting. Nonsense today, but it "is the place to be." Let us leave such an application on the conscience of manufacturers and we will consider indicator LEDs in more detail.

DIP (Dual In-line Package) or DIL (Dual In-Line - English. Double placement in line)

Interesting and aging types and types of DIP LEDs. The literal translation of such LEDs - DIP (DIL) double placement in line. By way of installation are defined as: PHT (Plating Through Holes - English. Through the hole in the board).

Typical representatives of this group in the classification are 3mm, 5mm, 8mm and 10mm LEDs. We have already said that these are obsolete types, since were pioneers in the formation of solid-state lighting. And industrial use is a big question.

Semiconductors of this type differ in color, material and bulb diameter 3mm, 5mm, 8mm, 10mm, etc. The choice is gorgeous. You can find chips for every taste and color from round to rectangular. The main advantage of any specimens in this group is low heat with a fairly good brightness. The main use is in electronic boards, running lines, various indicators (which is why this separation is taking place).

When viewed from the side of the design, the indicator diodes have a cylindrical shape with an integrated convex lens. Available in one color and multicolored (RGB).

Apart from this, there are types of OLED diodes (Organic Light Emitting Diode) - organic light-emitting diodes. Popular in the manufacture of backlight LCD screens, displays and televisions.

Super Flux Piranha

Piranha LEDs from this group have the best luminous flux characteristics. A design feature can be considered a rectangular shape with four leads (pins). To date, there are 4 colors: red, green, blue, white. Dimensions: 3mm, 5mm and Falt.

Piranha LEDs from this group have the best luminous flux characteristics. A design feature can be considered a rectangular shape with four leads (pins). To date, there are 4 colors: red, green, blue, white. Dimensions: 3mm, 5mm and Falt.

The main application of super-bright LEDs Piranha - cars and advertising.

Feature and advantage over the DIP diodes 3,5,10 mm - the presence of four pins. Due to this, a more “rigid” connection to the board is conditioned.

Pirana substrate is made of lead, because has great thermal conductivity. The operating temperature is quite wide, which allows the use of large input power. As for safety and environmental issues, the question remains ... Lead ... Not quite an eco-friendly material ... To put it mildly ...

The angle of dispersion of the light flux is wide - from 40 to 120 degrees.

If we draw a parallel on the applicability and relevance, then Piranhas still hold the palm.

A new kind of indicator - fiber LEDs

This is one of the new types and types of LEDs, which were presented to the general public by Korean manufacturers at the end of 2015. So far they are used only as individual fibers, but the moment when they can be used in the textile industry is not far off. And as soon as this day comes, they can be transferred with great confidence to the group of lighting LEDs.

This is one of the new types and types of LEDs, which were presented to the general public by Korean manufacturers at the end of 2015. So far they are used only as individual fibers, but the moment when they can be used in the textile industry is not far off. And as soon as this day comes, they can be transferred with great confidence to the group of lighting LEDs.

The production method is based on coating the substrate with polyethylene terephthalate impregnated with a PEDOT: PSS solution (poly-3,4-ethylenedioxythiophene polystyrene sulfonate). Next, the fibers cover the oled with a diode, dry and apply the final layer of lithium aluminum fluoride (LiAl).

Types and types of LED lighting

The most interesting and widely used types and types of LEDs - lighting. In everyday use diodes with white radiation are used. He, in turn, is divided into: cold white, warm white. By themselves, semiconductors cannot reproduce white. Therefore, several methods of obtaining white color are used.

The first is the RGB method. The cheapest technology for producing white diodes. But with its use the color rendering index worsens. About what it is - read the relevant material.

The second method is the most common. Putting phosphor on a blue or blue LED. This method is the most common. In this case, we get yellow and green colors, or red and green. This method is ideal if we want to get the color as close as possible to the luminous one.

SMD lighting LEDs

One of the most common types in the lighting group. Referring to the translation. Abbreviation SMD - Surface Mounted Device - English device surface mounted.

Structurally, these types are quite complex. Consist of an aluminum or copper substrate. The crystal itself is mounted on the substrate, soldered to the contacts of the housing in which the substrate is enclosed.

The crystal is covered with a lens, in some cases only with a phosphor. Up to three diodes can be placed on one substrate, depending on the application of the future light source.

Common type of LED - COB

Other, the most common and fashionable types are COB type diodes (Chip On Board). In this case, from one or more crystals are mounted on one board (substrate). They are filled with phosphor. In this form, we get a LED with high brightness. This technology has simplified and significantly reduced the cost of manufacture of lighting LED devices. The luminous flux of COB diodes is an order of magnitude greater than that of SMD.

Other, the most common and fashionable types are COB type diodes (Chip On Board). In this case, from one or more crystals are mounted on one board (substrate). They are filled with phosphor. In this form, we get a LED with high brightness. This technology has simplified and significantly reduced the cost of manufacture of lighting LED devices. The luminous flux of COB diodes is an order of magnitude greater than that of SMD.

The main purpose is lighting. While COB diodes can also be used as indicators.

In terms of maintainability, COB is the least preferred, since in case of a burnout, you will have to change the entire matrix.

And by the way, I have long noticed that in COB chips it is quite difficult (for a simple inhabitant) to determine the number, size of crystals. And accordingly, compare the obtained measurements (calculations) with the stated characteristics of the light sources.

Well, the latest novelty in 2015 in solid-state lighting - filament LEDs.

New kind of LED - filament

This type of diode was formed not so long ago. But immediately fell in love with buyers. And it is not surprising, because at the same power (compared to COB or SMD) we can get more illumination.

This type of diode was formed not so long ago. But immediately fell in love with buyers. And it is not surprising, because at the same power (compared to COB or SMD) we can get more illumination.

While the main application of filament LEDs - LED lamps. Filament LEDs are mounted on a glass or sapphire substrate. Technology - Chip-On-Glass. As a result, the light spreads to 360 degrees. Enough interesting and "far-reaching" technology.

Conclusion

In principle, the types and types of LEDs indicated in the article are incomplete and this classification can be extended by applying a number of subspecies and classes. Someone, it seems simple. Someone is right, someone is funny. But due to the fact that there is no definite “scientific concept” on the distribution of LEDs, it’s for a general understanding of how LEDs can be divided into the types and classes we received. What, in principle, and sought.

In contact with