CABLING

WITH ISOLATION FROM CROSSED POLYETHYLENE

In the preparation of materials, “Recommendations for laying and installation of cables with insulation of cross-linked polyethylene voltage of 10, 20 and 35 kV” (information from RusCable. Ru) were used, taking into account other data on cable of cross-linked polyethylene.

1. The main provisions

Any company operating electrical networks with a voltage of 6-10 kV and above, use power cables.

Cable lines have a huge advantage over overhead lines, as they take up less space, are safer, more reliable and more convenient to operate.

The vast majority of cables used in Russia and the CIS countries - impregnated with paper insulation (PBI), have numerous disadvantages:

High damageability;

Restrictions on load capacity;

Restrictions on the difference in gasket levels;

Low adaptability mounting clutches.

In the present time, given the above disadvantages, paper-insulated cables are actively replaced by cables with insulation made of cross-linked polyethylene.

The leading energy systems of the country in the construction of new cable lines or repair existing actively use cables with insulation of cross-linked polyethylene.

The transition of paper-impregnated insulation (PSI) cable to cable with insulation made of cross-linked polyethylene (XLPE) is associated with the ever-increasing requirements of operating organizations to the technical parameters of cables. In this regard, the advantages of cables from the POC are obvious.

In the table (according to the data of the Forum Electro GROUP), the main indicators of the average voltage cable are given:

| Main factors | Type of cable insulation |

|

| impregnated paper | cross-linked polyethylene |

|

| 1 Long-term working temperature, ° С | ||

| 2. Temperature at overloads, ° С | ||

| 3. Resistance to short-circuit currents, ° С | ||

| 4. Load capacity,% | ||

| When laying in the ground | ||

| When laying in the air | ||

| 5. Level difference when laying, m | not less than 15 | no limit |

| 6. The complexity of the installation and repair | high | low |

| 7. Reliability indicators - specific damage, - pieces / 100 km year |

||

| In lead shells | about 6 * | |

| In aluminum shells | about 17 * | 10-15 times lower |

_______________

* according to the ISS "Mosenergo", A.S. Svistunov. Direction of development work.

The advantages of cross-linked polyethylene cable are:

Higher operational reliability;

Increasing the working temperature of cable cores with XLPE insulation up to 90 ° С, which ensures high cable carrying capacity;

Solid insulation, which allows laying a cable with XLPE insulation in areas with a large elevation difference, incl. vertical and inclined collectors;

The use of polymeric materials for insulation and sheath, providing the ability to lay the cable of XLPE without preheating at temperatures down to –20 ° C;

The smaller weight, diameter and radius of a bend of a cable that facilitates laying on difficult routes;

Low moisture absorption;

Specific damageability of the cable with XLPE insulation is 1-2 orders of magnitude lower than that of the cable with impregnated paper insulation;

High tocothermic stability during short circuit;

Insulating material allows to reduce dielectric losses in the cable;

Large cable lengths;

lower costs for reconstruction and maintenance of cable lines;

More environmentally friendly installation and operation (no lead, oil, bitumen);

Increase the service life of the cable.

The use of 6-10 kV insulated cables with XLPE allows to solve many problems in terms of power supply reliability, optimize and in some cases even change traditional network diagrams.

Currently, in the USA and Canada, the share of cables with XLPE insulation is 85%, in Germany and Denmark -95%, and in Japan, France, Finland and Sweden, only XLPE-insulated cable is used in distribution networks of medium voltage.

2. Polyethylene crosslinking technology

Polyethylene at the present time is one of the most used insulation materials in the manufacture of cables. But initially thermoplastic polyethylene has serious drawbacks, the main of which is a sharp deterioration of mechanical properties at temperatures close to the melting point. The solution to this problem was the use of cross-linked polyethylene.

The unique properties of XLPE cables are required to the insulating material used. The crosslinking or vulcanization process at modern cable companies is carried out in a neutral gas environment at high pressure and temperature, which allows to obtain a sufficient degree of crosslinking throughout the entire insulation thickness.

The term “crosslinking” (vulcanization) implies the processing of polyethylene at the molecular level. The crosslinks formed during the crosslinking process between the macromolecules of polyethylene create a three-dimensional structure that determines the high electrical and mechanical characteristics of the material, less hygroscopicity, a larger operating temperature range.

There are three main ways of crosslinking polyethylene: peroxide, silane and radiation. In the world of cable industry in the production of power cables used the first two.

Peroxide cross-linking of polyethylene occurs in a neutral gas environment at a temperature of 300-400 ° C and a pressure of 20 atm. It is used in the manufacture of medium-high voltage cables.

Silane crosslinking is carried out at a lower temperature. The application sector of this technology covered low and medium voltage cables.

In 1996, ABB Moscable, using peroxide cross-linking technology, became the first Russian manufacturer of cable with XPS. For the first time in Russia, the production of cable from silane-cross-linked polyethylene in 2003 was mastered at the Perm OJSC Kamkabel.

There are some features of the production and operation of such cables.

3. The design of cables XRT.

Cables are mainly produced in single-core execution (), but are also available in three-core versions (), and the use of various types of sheaths and the possibility of sealing allows the cable to be used both for laying in the ground and for cable installations, including for group installation:

| Insulated cable sheaths of XLPE | Abbreviation | Areas of use |

| Of PE | laying on the ground in the air |

|

| Reinforced PE | Poo | laying on the ground in difficult areas |

| PVC plastic | in cable structures, in industrial premises - in dry soils |

|

| Low flammability PVC compound | group laying - in cable constructions - in industrial premises |

|

| Cables with longitudinal sealing | g, 2g, gzh (after the designation of the shell) | for laying in soils with high humidity in damp, partially flooded premises |

Additional designations for cables with sealing elements in the design:

"G" - sealing the metal screen with water-blocking tapes;

“2g” - alumopolymer tape over the sealed screen;

"ГЖ" - a water-blocking powder or filaments is used in the secondary conductor.

The design of the cable with insulation of XLPE for low and medium voltage:

1. Conductive multi-wire sealing core:

Aluminum (Apvpg, Apvpug, Apvvg, Apvvng-LS, Apvpug2g);

Copper (PvPg, PvPug, PvVg, PvVng-LS, PvPu2g).

2. Electrically conductive screen of silane cross-linked polyethylene composition.

3. Insulation of silane-cross-linked polyethylene.

4. Electrically conductive screen of silane cross-linked polyethylene composition.

5.Water blocking conductive tape.

6. Shredded wire screen.

7. Copper tape.

8. Separation layer:

Water blocking conductive tape (ApvPu2g, PvPu2g);

Electrically insulating crepe paper (ApvPg, PvPg, ApvPug, PvPug, ApvVg, PvVg);

Lentaalumopolyethylene (APvPu2g, PvPu2g).

9. Shell:

Polyvinyl chloride plastic (Apvvg, PvVg);

Polyvinyl chloride low fire risk (Apvvng-LS, PvVng-LS);

Polyethylene (APVPg, PvPg, APVPug, PvPug, APVPu2g, PvPu2g).

Fig. one . XLPE Single Cable

Fig. 2 . Three-core XLPE cable

4. Features of installation of power cables with cross-linked polyethylene insulation

1) Laying cables with insulation from cross-linked polyethylene is recommended at an ambient temperature not lower than 0 ° C. It is allowed to run cables with XLPE insulation without heating at ambient temperature not lower than -15 ° С for cables with sheath of PVC and plastic -20 ° С for cables with sheath of polyethylene. At lower ambient temperatures, the cable should be heated by exposure in a heated room for at least 48 hours or using a special device to a temperature not lower than 0 ° C, while laying should be done in a short time (no more than 30 minutes). After laying the cable should be immediately filled with the first layer of soil. The final backfilling and compaction of the soil should be done after the cable has cooled. Cables should not be laid at an ambient temperature below -40 ° C.

2) The minimum bending radius of cables with XLPE insulation when laying should not be less than 15D n for single and three core cables and 12Dh for three twisted together cable cables, whereDh -free cable diameter or twisted diameter for three twisted together multiplex cables. With careful control of bending, for example, by using an appropriate template, the bending radius of the cable can be reduced to 8Dh. In this case, it is recommended to heat the cable in a place that bends a temperature of 20 ° C.

3) Unwinding of cable with insulation of cross-linked polyethylene from the drum should be performed using the required number of walk-through and corner rollers. The unwinding method used should ensure cable integrity. During the laying of the cables, the POC should be carried out with the help of a tensioning stocking laid on the outer sheath, or for conducting the conductor using a wedge grip. The efforts arising during the tension of the cable with insulation made of cross-linked polyethylene with a multiwire aluminum conductor should not exceed 30 N / mm 2 of the nominal cross section of the conductor, cable with an aluminum conductor (marked “ozh”) - 25 N / mm 2, the cable with the copper conductor - 50 N / mm 2. If three single-core cables with one common steel stocking are simultaneously laid, the calculation of the reinforcement takes into account:

1 nominal cross-section of the conductor, if the cables are twisted together;

2 nominal cross-section conductors, if the cables are not twisted.

The efforts of the cable when laying must be calculated when designing the cable line taken into account when ordering the cable. The traction winch must be equipped with devices that allow you to control the cable tension force, record the tension force during the entire cable pulling process and automatically turn off the traction winch if the tension force exceeds the allowable value.

4) Cables with XLPE insulation should be laid with a margin of length 1¸ 2%. In trenches and on solid surfaces inside buildings and structures, the reserve is created by laying the cable "snake", and for cable structures (brackets) this stock is created by the formation of a sag. Laying the cable in the form of rings (turns) is not allowed.

5) Metal cable structures should be grounded in accordance with the applicable documentation.

6) When laying the cable line, the TES cables of the three phases should be laid in parallel and be arranged in a triangle or in the same plane. Other arrangements should be agreed with the manufacturer.

7) When laying the plane, the clear distance between two adjacent cables of the same cable line must be at least the outer diameter of the XLPE cable.

8) When the triangle is positioned, the cables are fastened along the length of the cable line (with the exception of sections near the couplings) at a distance of 1¸ 1.5 m, at the bends of the track - 1m. When laying in the ground should take into account that when backfilling with soil cables should not change their position. Cables laid in the plane in cable structures in the air should be fixed along the line at a distance of 1¸ 1.5 m. Staples and other fasteners for fastening single-core XLPE cables, as well as fastening tags on cables should be made of a non-magnetic material. When attaching cables, it is necessary to take into account possible thermal expansion of cables and mechanical loads arising in the short circuit mode.

9) All ends of the cable after cutting should be sealed with heat shrinkable caps to prevent the ingress of moisture from the environment. During the laying of the cables, the condition of the shells and protective caps should be monitored.

5. Ways of laying cables

Polyethylene-insulated cables can be laid in the ground (trench), in cable structures (tunnels, galleries, racks), in blocks (pipes), in production rooms (in cable channels, along walls).

When laying cables in the ground, it is recommended to lay no more than six cables in one trench. With more cables, it is recommended to lay them in separate trenches. Cable laying can be carried out by single cables, so and connected in a triangle.

Laying cabling in tunnels, overpasses and galleries is recommended when there are more than twenty cables in one direction. Laying cables in blocks is applied in conditions of great constraint on the highway, at the intersections with railway tracks and passages, with the probability of a metal spill, etc.

When laying metal structures, it is possible to use different types of fastenings in a video vault, click, or attachment points.

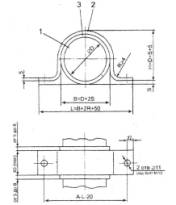

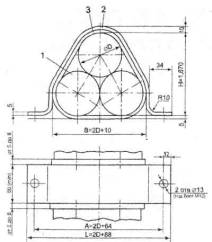

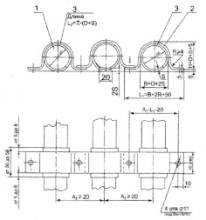

Examples of cable fastening using brackets (Fig.,,).

All sizes are in millimeters. Fasteners (bolts, nuts, washers) are not shown.

D - outer diameter of the cable,S - gasket thickness (from 3 to 4 mm).

Fig. 3 . Single cable fixing

Legend:

1 cable; 2 - clamp (bracket) made of aluminum or aluminum alloy; 3 - rubber strip or polyvinyl chloride .

Fig. four . Mounting of three cables in a bundle (delta)

Legend:

1- cable; 2- clamp (bracket) made of aluminum or aluminum alloy 5 mm thick; 3 - a strip of rubber or polyvinyl chloride with a thickness of 3 ¸ 5mm.

Fig. five . Fixing three cables

Legend:

1- cable; 2- clamp (bracket) made of aluminum or aluminum alloy; 3- rubber or polyvinyl chloride gasket.

6. Cable laying technology

Cabling is carried out by a brigade of 5-7 people.

Approximate scheme of the installation of workers during cable pulling:

Drum, on a brake - 1 person;

Retraction cable cable - 1 person;

Cable run down the trench (entrance, exit from the tunnel) - 1 person;

On the winch - 2 people;

Escort cable end - 2 people.

In addition, it is necessary to provide for one person:

At every corner;

On each pipe passing through partitions or ceilings, at the entrance to the chamber or building.

At the same time, the tension of the three cables behind the device for grouping the cables must be 2 people to hold the cable in a triangle.

Laying speed should not exceed 30 m / min and should be selected depending on the nature of the route, weather conditions and the effort of tension.

When exceeding the allowable amount of stress, it is necessary to stop the gasket and check the correctness of the installation and the condition of the linear and angular rollers, the presence of lubricant (water) in the pipes, and also check the cable for possible jamming in the pipes.

When running down a trench or entering a tunnel, make sure that the cable does not slip off the rollers and does not rub against pipes and walls in the aisles. At the entrance to the pipes, it is necessary to ensure that the protective covers of the cables at the edge of the pipe are not damaged.

If the cable sheath is damaged, it is necessary to stop the gasket, inspect the damage site and decide on the method of repairing the sheath.

Accompanying cable ends must ensure that the cable goes over the rollers, corrects the rollers, if necessary, and also guides the end of the cable.

Kabelvytyagivaetsya so that when laying it according to the project, the distance from the top of the end coupling or from the conditional center of the coupling is not less than 2 m. When determining the stock, it should be noted that there is enough cable residue for mounting the coupling. Disconnect traction cable and remove stocking or grip from cable end. If there is a cable on the drum for several sections of the route, or if the cable length is significantly longer than the length of the section, it is necessary to cut the cable.

After trimming the cable, it is necessary to encapsulate the ends of the cables. For more reliable sealing of the ends of the cables, it is possible to apply double dripping. Insulate the inner core onto the electrically conductive layer through the cable insulation, and the anterior outer cap onto the inner core and onto the cable jacket. It is also possible to apply a layer of molten bitumen on the edge of the cable with a perekapka.

If necessary, start the cable ends in chambers, wells, cable rooms. At the same time it is necessary to observe the permissible bending radii of the cable. Remove the cable from the rollers, lay and fix it on the project.

When laying the old material, make powder of the cable with a sand-gravel mix or fine soil with a thickness of at least 100 mm and test the cable jacket.

Magazine "Pricing reasonable rationing in construction", November 2010, № 11

In accordance with

pretext

The circumstantial revolutions “in accordance with + noun” can be distinguished by punctuation marks (commas). For details on the factors affecting the placement of punctuation marks, see Appendix 1. ()

Exactly at three o'clock , in accordance with labor laws, brought the keys doctor Ambrose Ambruazovich Vybegallo. A. and B. Strugatsky, Monday begins on Saturday. Material collection process in accordance with the genre of non-fiction requires the active role of the author, who defines the essence of the work as a problem S. Aleksievich, Zinc boys. God and her name determined in accordance with matter - Silakova. V. Astafiev, Sad Detective.

Dictionary-reference to punctuation. - M .: Reference and information Internet portal GRAMOTA.RU. V.V. Svintsov, V.M. Pakhomov, I.V. Filatova. 2010 .

See what is "in accordance with" in other dictionaries:

Declaration of Conformity - Wikisource has texts on the topic ... Wikipedia

declaration of conformity - a document certifying the compliance of the product being released into circulation with the requirements of technical regulations; A source …

GOST R 54009-2010: Conformity assessment. Application of marks indicating compliance - Terminology GOST R 54009 2010: Conformity assessment. The use of marks indicating compliance with the original document: 3.5 declarant: Applicant who accepted the declaration of conformity and registered it in the prescribed manner. Definitions ... ... Vocabulary-terms reference terms and technical documentation

supplier’s declaration of conformity - 01.02.51 statement of conformity of the [implementation conformance statement; ICS]: A statement made by the supplier regarding the compliance of the delivery item with the established specifications, which provides detailed information on the sales ...… Vocabulary-terms reference terms and technical documentation

certificate of compliance with protocol implementation - A summary of the capabilities of the system under test. Note. The protocol implementation conformance certificate (PICS) contains information on ACSI. As a rule, this information may relate to additional options, special restrictions or ... ... Technical Translator's Guide

implementation conformity claim - 2.1.13 application for compliance with the implementation; ZSR: An application prepared by a supplier of an implementation or an information technology system, declaring compliance with one or more technical requirements, determining which possibilities ... ... Vocabulary-terms reference terms and technical documentation

conformity mark - 3.1 mark indicating compliance: The designation used to convey to the acquirer and other interested parties information on the compliance of the object with the established requirements and the confirmation of conformity of this object ... ... Vocabulary-terms reference terms and technical documentation

Correction of grades in accordance with existing structures. - 4.05.5. Correction of grades in accordance with existing structures. Before laying the surface layer of the concrete solution, the markings for the installation of metal frames and gratings should be adjusted. Frames, grilles and covers are removed and ... ... Vocabulary-terms reference terms and technical documentation

According to With and According to - preposition 1. with the creator. pad Uses when indicating what acts as: 1) the basis of the action, which is the determining factor for the action; according to what l., according to what l., in accordance with what l. and 2) the reasons for the action, that ... ... Modern Dictionary of the Russian language Ephraim

statement of conformity - 4.18 statement of conformity: A statement of conformity of the object under study to certain requirements.

CONFORMITY, a literary device related to a symbol, establishes an internal connection between poetically perceived sounds, colors, lines, forms, smells, tactile and other sensations. The match is related to the primary value ... ... Literary Encyclopedia

Conformity - CONFORMITY, a literary device related to a symbol, establishes an internal connection between poetically perceived sounds, colors, lines, forms, smells, tactile and other sensations. Compliance is associated with the primary ... ... Dictionary of Literary Terms

CONFORMITY, compliance, cf. The relation between something, expressing consistency, equality in something or something in some respect, harmony. Compliance with the performance of the task. They have full compliance interests. Between him ... ... Explanatory Dictionary Ushakov

Relation, similarity, analogy, agreement, proportionality, symmetry, harmony. Wed . .. See agreement ... Synonym dictionary

conformity - Conformity, if this noun is flexible enough in combination with other words (it can be said that compliance with what, and between what and what, and what), then the complex preposition formed with its help is consistent (note: it ends in Dictionary of Russian language errors

COMPLIANCE, in geometry, is a property of two geometrical figures, whose angles, sides and points of one are in a similar relation to angles, sides and points of the other. In the theory of sets they say that the sets A and B are mutually ... ... Scientific and Technical Encyclopedic Dictionary

CONFORMITY - CONFORMITY. An element of one language that functionally corresponds to an element of another in a given context. There are permanent S. and variant, or contextual ... New vocabulary of methodological terms and concepts (theory and practice of language teaching)

Conformity - (mat.) see Display ... Economics and Mathematics Dictionary

conformity - CONFORMITY1, harmonization, coordination, harmonization, proportionality CONFORMITY, harmony, harmony, consonance, conformity, proportionality, book. adequacy, outdated. consent LEGAL RESPONSIBLE, ... ... Thesaurus of the synonyms of the Russian language

Books

- Methodical materials on support of the procedure for certification of pedagogical workers for compliance with their position, the team of authors. METHODICAL MATERIALS ON SUPPORTING THE PROCEDURE OF CERTIFICATION OF PEDAGOGICAL WORKERS FOR COMPLIANCE WITH THE POSITIVE POSITION. MCSC ...

- Methodical materials on support of the procedure for certification of teaching staff for compliance with the position held. (ICCA), Borovik M, aut.-comp. The collection contains practical materials on the preparation and conduct of the certification procedure for teachers in order to confirm compliance with their positions according to the Procedure ...